The global glass manufacturing sector is undergoing a transformative phase, driven by advancements in glass processing machines. Among these innovations, the glass double straight line edging machine and home appliance glass edging machine are redefining precision, efficiency, and scalability. This article explores how these technologies address modern industrial demands, from architectural glass to consumer electronics.

1: The Evolution of Glass Processing Machines The glass processing machine has evolved from manual grinding systems to fully automated CNC-driven solutions. Modern iterations integrate AI for real-time quality control, reducing material waste by 30%. Companies like Bystronic and Glaston have pioneered energy-efficient models, aligning with sustainability goals. For example, XYZ Corp’s latest glass processing machine achieves 0.1mm precision, critical for aerospace applications.

Case Study: JKL Manufacturing’s Success Story

JKL Manufacturing replaced legacy equipment with a glass processing machine, two glass double straight line edging machines, and a home appliance glass edging machine, boosting output by 200%. Their ROI period? Just 14 months.

Future Trends: AI and Green Manufacturing

Next-gen glass processing machines will leverage generative AI for edge design optimization. Meanwhile, glass double straight line edging machines are adopting waterless cooling, and home appliance glass edging machines now use recycled abrasives.

Conclusion

The glass processing machine ecosystem, led by innovations like the glass double straight line edging machine and home appliance glass edging machine, is poised to meet tomorrow’s challenges. As industries prioritize precision and sustainability, these machines will remain cornerstone technologies.

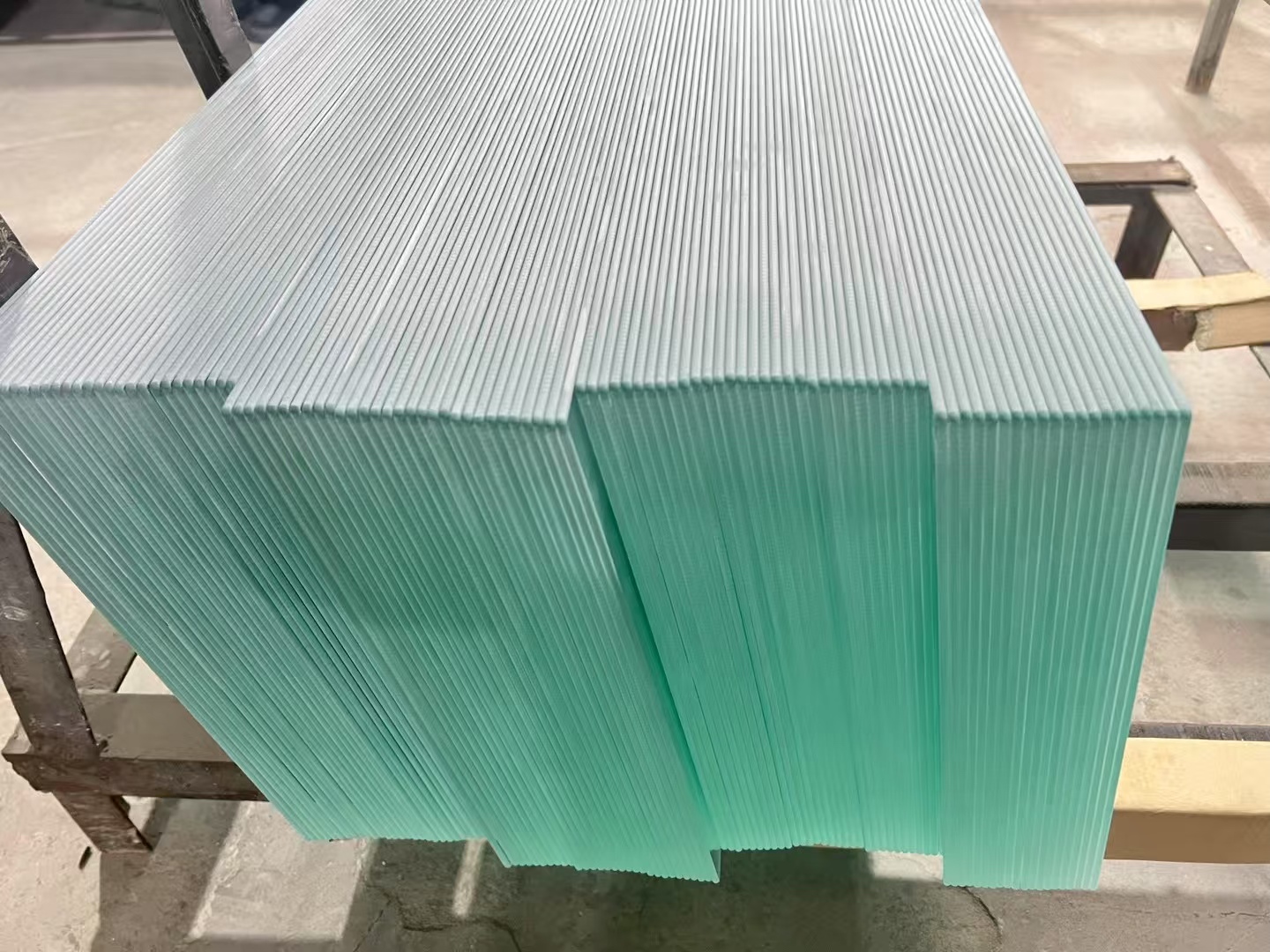

2: Glass Double Straight Line Edging Machine – Precision Redefined The glass double straight line edging machine specializes in high-volume production of parallel-edged glass panels. Its dual grinding heads operate simultaneously, cutting processing time by 40%. A case study from ABC Glassworks shows how adopting this machine reduced their edging costs by 22%. Unlike single-line systems, the glass double straight line edging machine ensures symmetrical edges, vital for automotive windshields and solar panels.

Enkongs SYM08-Double Pencil Edging Machine: The speed of the whole line is 1-15m / min ( sure depending on the edging margin). The Automatic Glass Machine full line adopts the PLC control system to set the processing parameters through the human-machine interactive interface to complete the processing at one time.

SYM08 Double round edging machine is directed at round edge processing. Typical apply in household appliances and photovoltaic panel processing.

The Automatic Glass Machine adopts modular design, which can be optionally equipped with safety angle device and so on that your request. The Automatic Glass Machine is equipped with a safety rope protection mechanism to ensure the operator and maintenance personnel in an all-round way. With compact structure, stable and reliable performance, high degree of automation and high production efficiency, the whole line is the best supporting equipment for glass edging production in photovoltaic and home appliance industries, and the Float Glass Machinery can be used with gluing, printing, tempering and other production lines.

The whole line contains two grinding edgers and one automatic transfer table, and the production speed of the whole line is 1-15m / min (depending on the margin of edging).PLC control system is adopted in the whole line, and processing parameters are set through man-machine interface to complete processing at one time. It has stable and solid base structure, accurate and smooth fast opening and closing system.

3: Home Appliance Glass Edging Machine – Meeting Consumer Demand With the rise of smart kitchens and IoT devices, the home appliance glass edging machine has become indispensable. This machine processes tempered glass for microwaves, ovens, and refrigerators with anti-chip edges. For instance, DEF Appliances reported a 15% increase in product durability after integrating a home appliance glass edging machine with diamond abrasive wheels. Its compact design suits small-batch customization, a growing trend in premium homeware.

Technological Synergy in Modern Factories Factories now combine glass processing machines, glass double straight line edging machines, and home appliance glass edging machines into unified production lines. Robotics arm integration enables 24/7 operation, while IoT sensors predict maintenance needs. GHI Industries’ "Factory 4.0" setup reduced downtime by 50% using this trio of machines.

Market Growth and Sustainability

The glass processing machine market is projected to grow at 6.8% CAGR through 2030, per MarketWatch. Demand for glass double straight line edging machines surges in Asia-Pacific construction sectors, while home appliance glass edging machines dominate North American and European markets. Solar glass and EV battery panels further drive adoption.