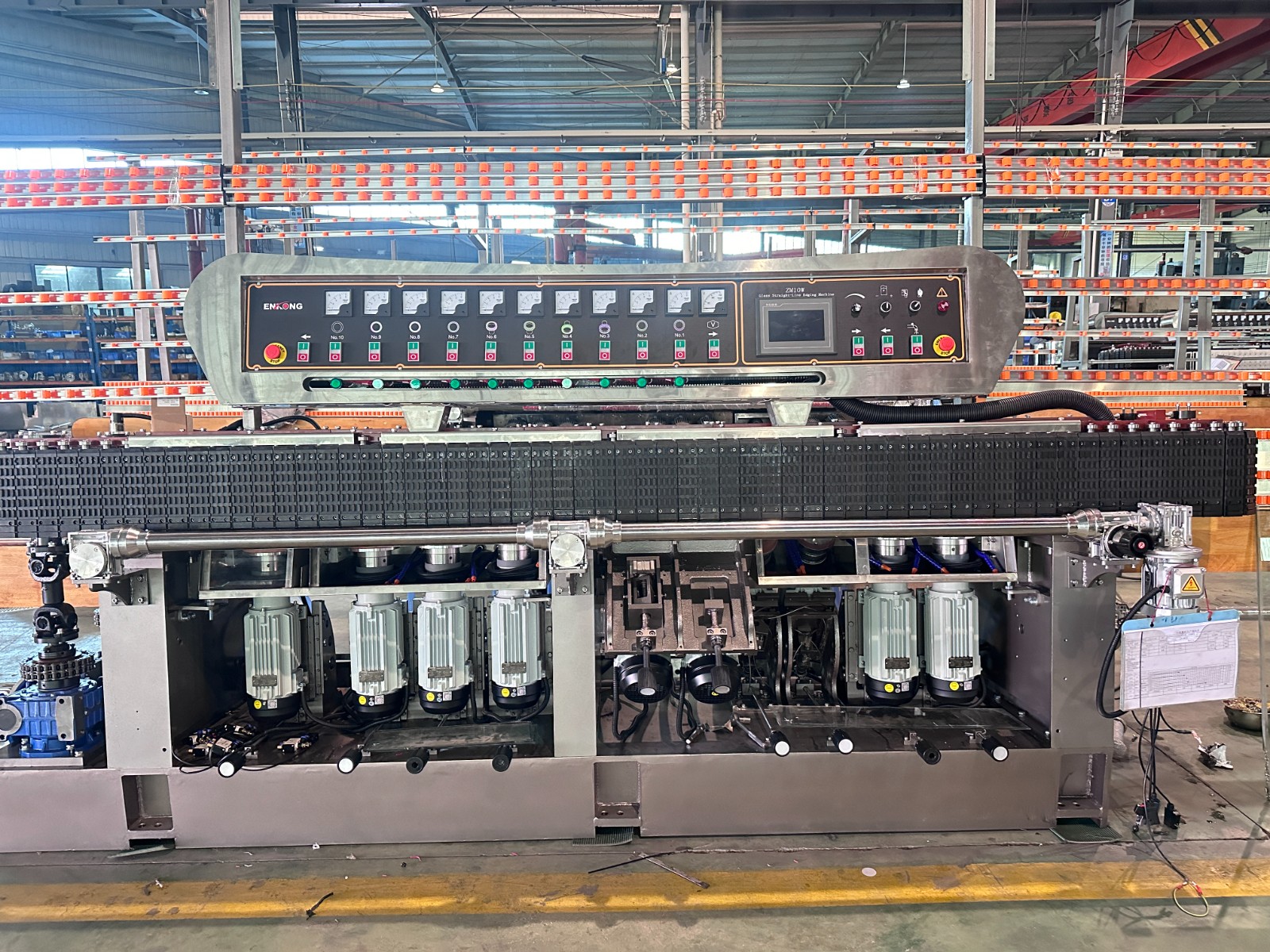

Product Description

1.ZM10W is applicable to processing the straight-line edge and 45° arrises of glass sheets of diverse sizes and thicknesses. The rough grinding, fine grinding, polishing of the flat edge, and grinding of the bottom edge can all be accomplished simultaneously.

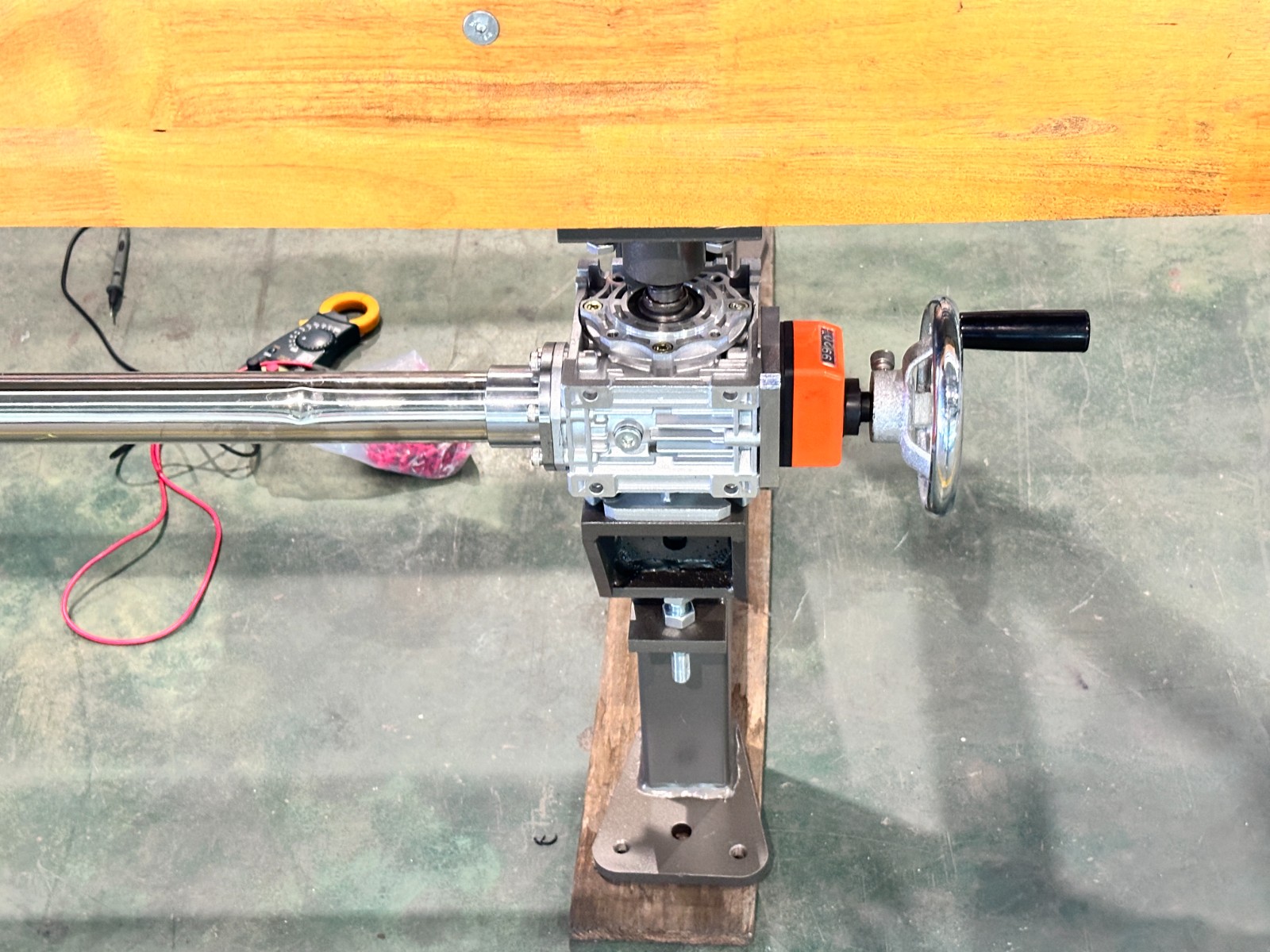

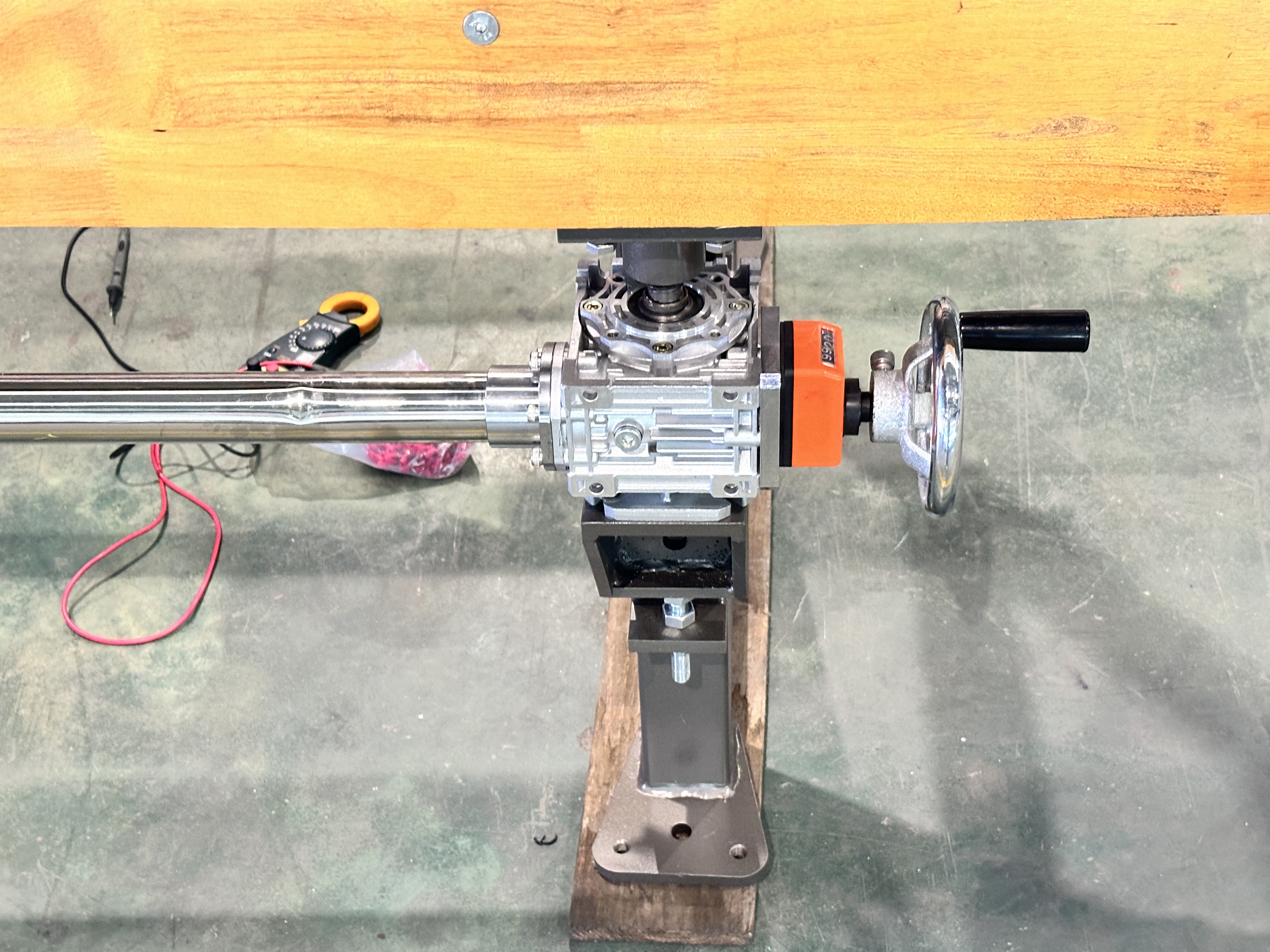

2.A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually.

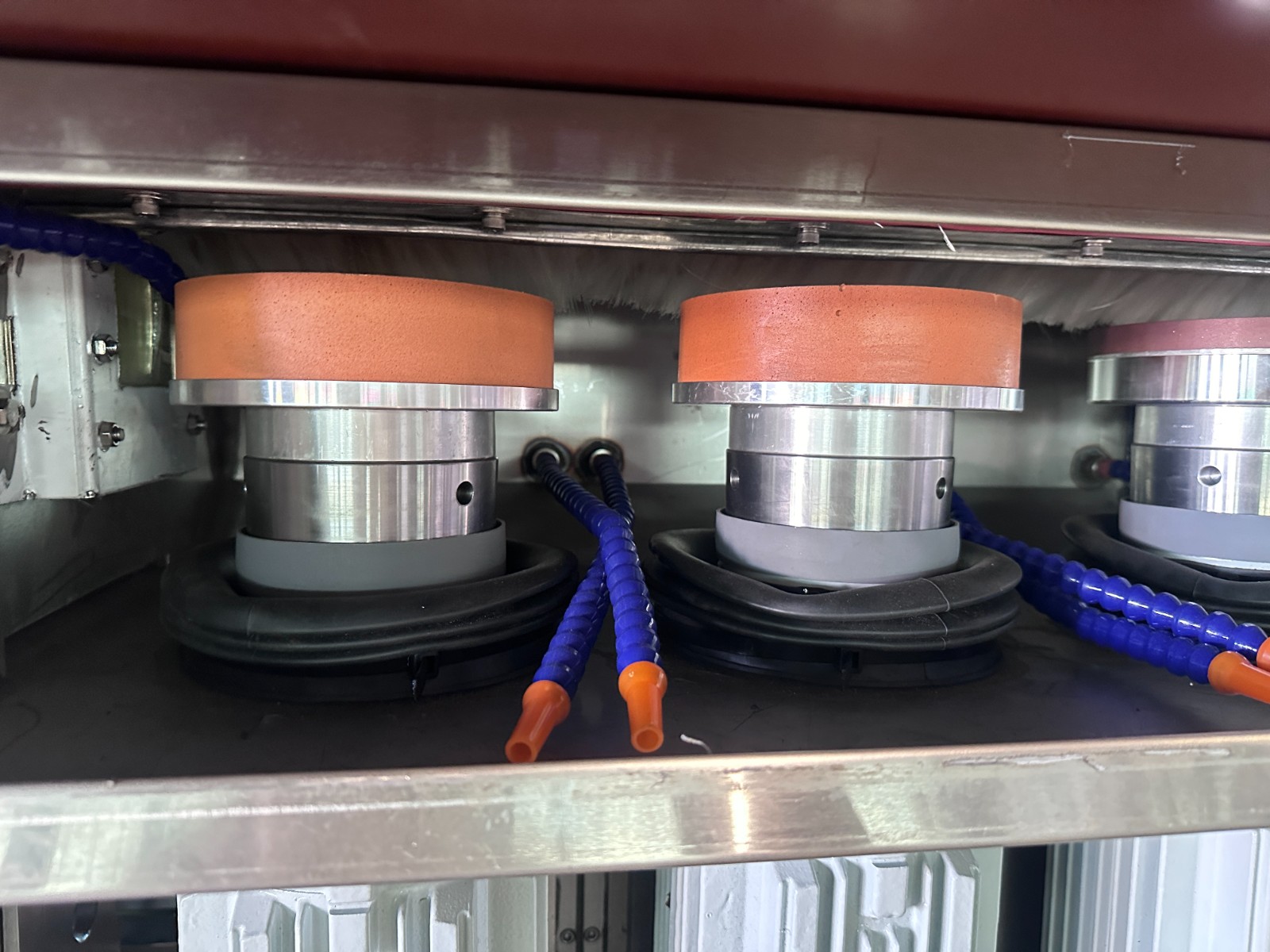

3.(Independent wool felt wheel + the cerium oxide ) make the flat edge more shining.

4.Input and output conveyor adopt timing belt which can improve the transmission precision.

5.When adjusting different processing thicknesses, the former arrises grinding head can move simultaneously along with the front beam.

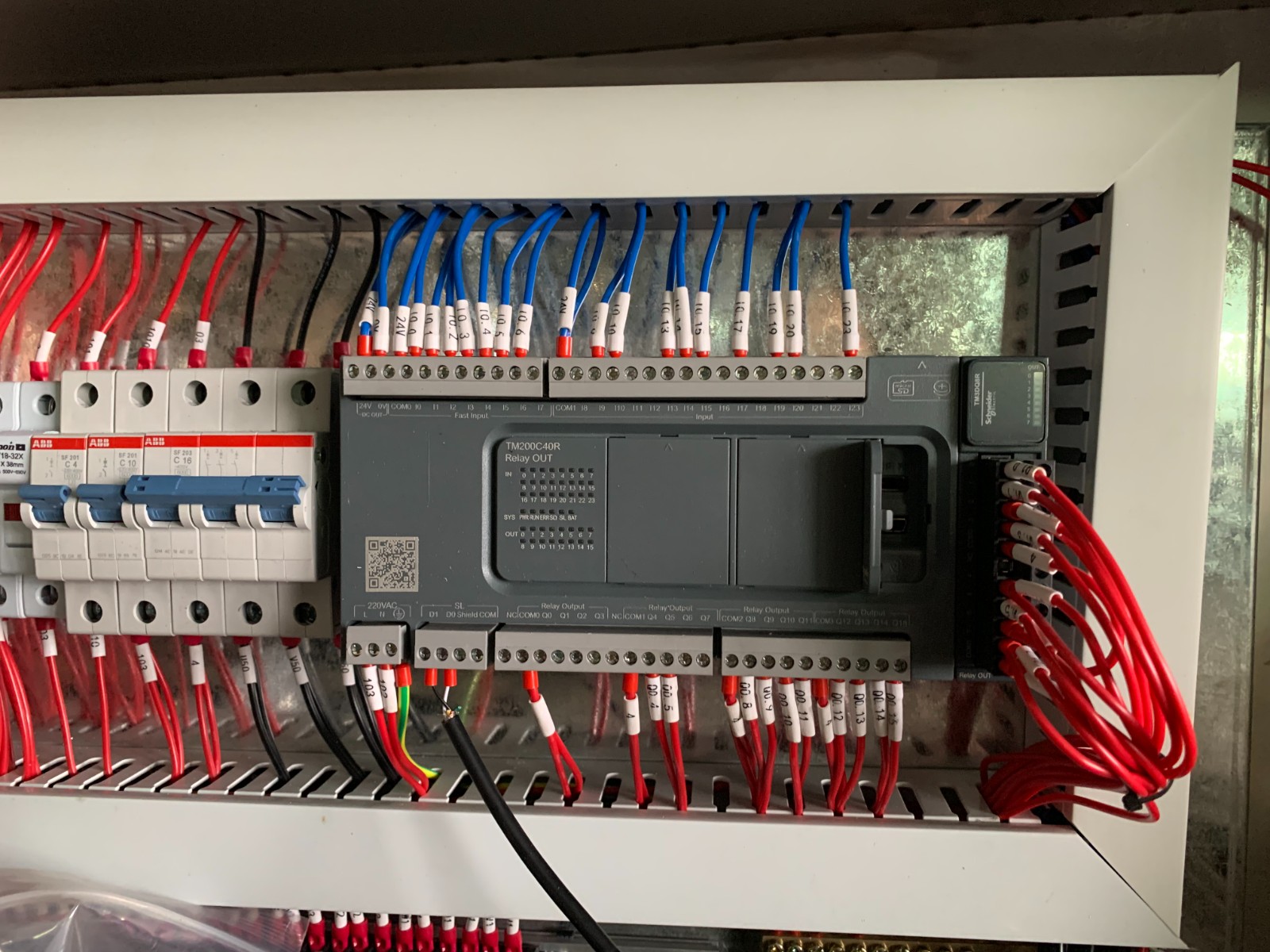

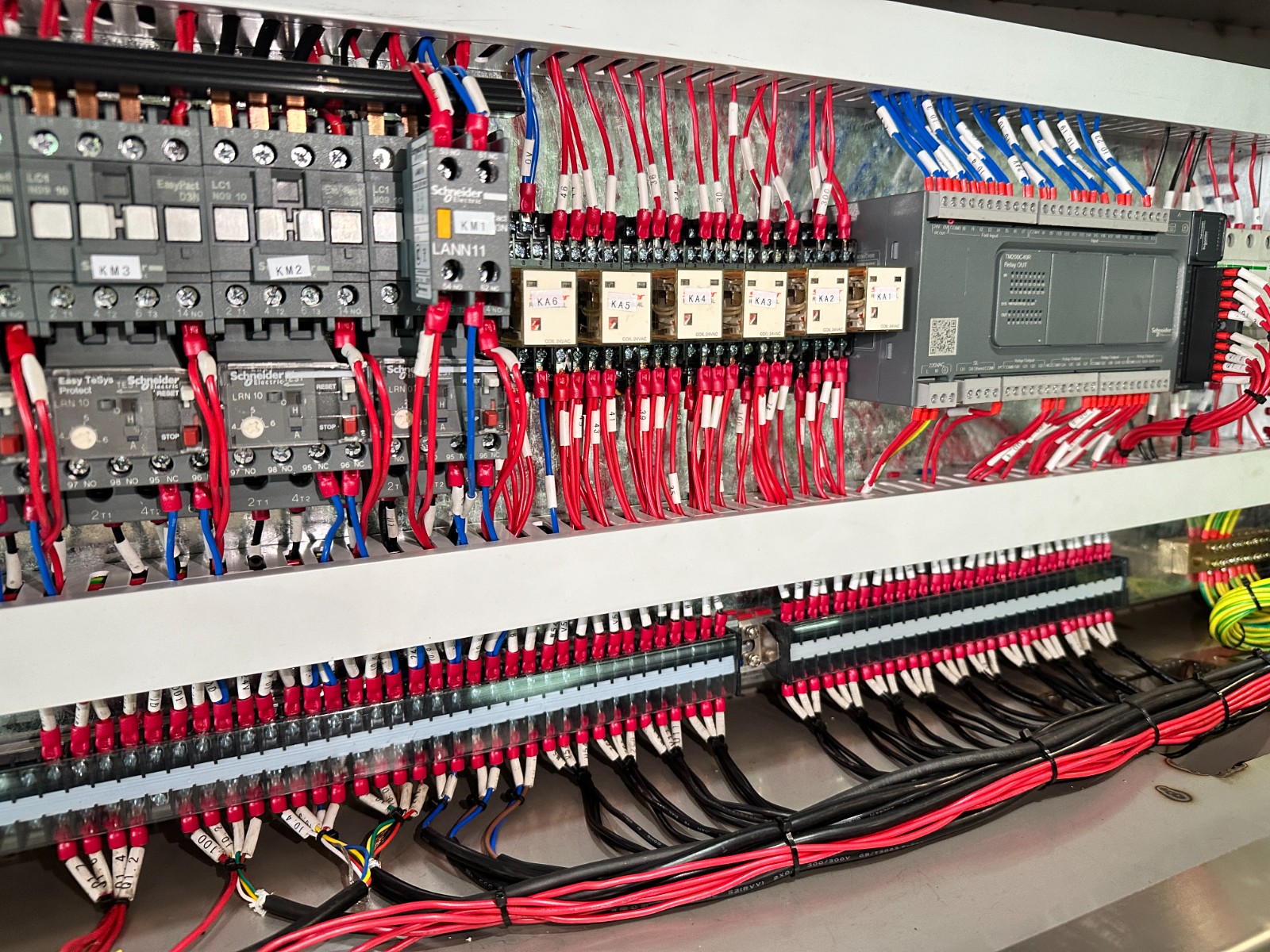

6.The electrical elements with famous ABB/ Schneider brand.

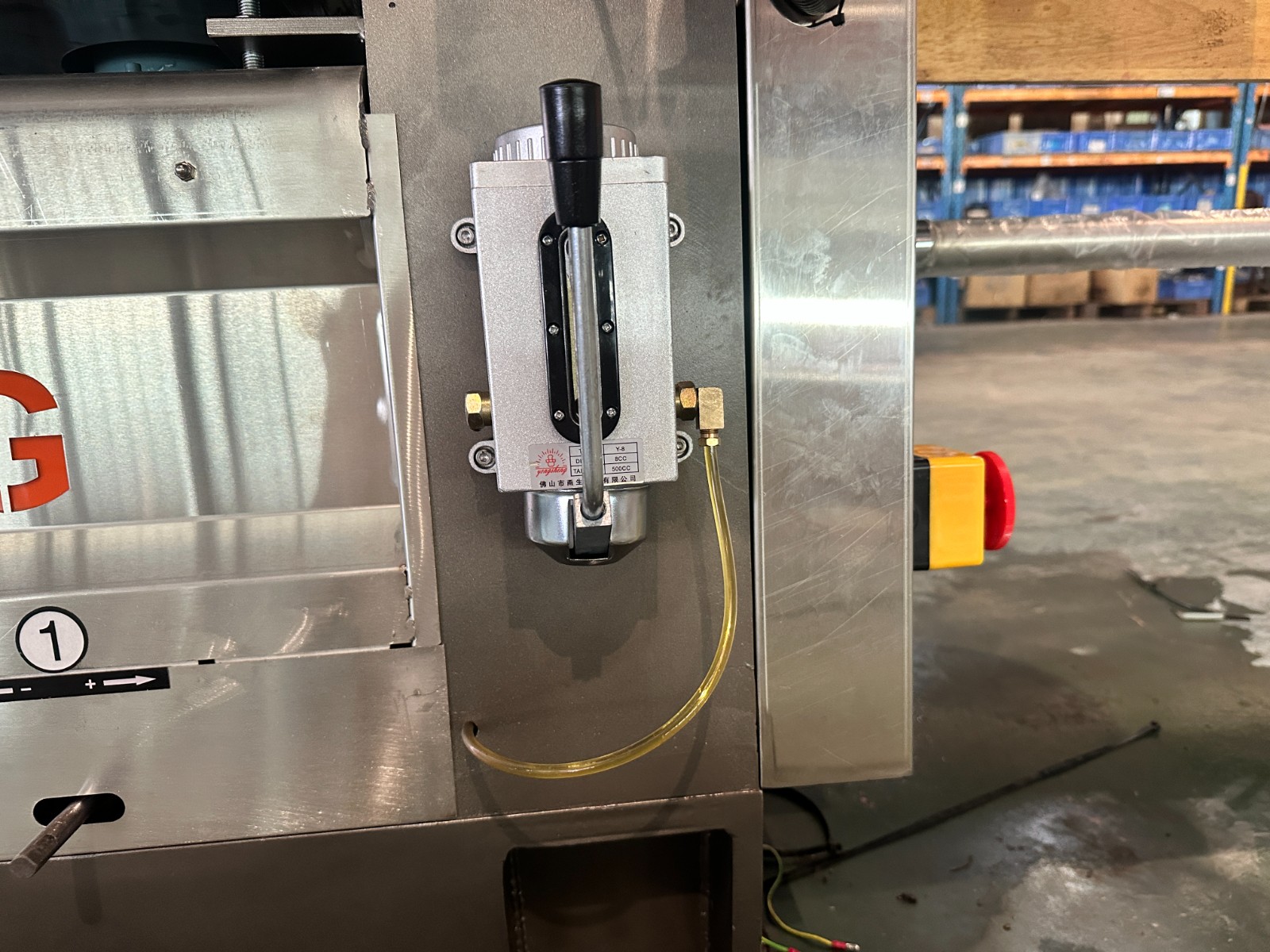

7.All mechanical feeding parts with lubricating system.

8.It can continuously process for the same thickness with different sizes. It can be combine as vertical edging production line. it made up by 4sets of edgers+3sets of turning table+1set of vertical washing machine. This production line is special for processing glass shower doors.

9.ZM10W Edger with three operation mode: Manual. Digital display and PLC Control+touch screen+pneumatic polishing.

10.ENKONGS was set up in 2006, one of the famous manufacturers of glass equipment.We has our own CNC center to processing 80% mechanical parts for our glass machine. Quality control in the house.

11. ENKONGS accepts reasonable custom-made

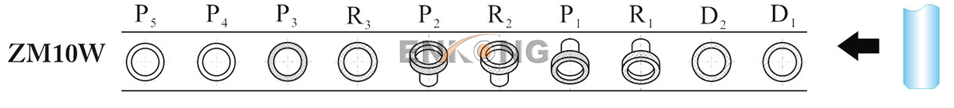

Grinding wheel arrangement

| No. | Wheels | Specification | Function |

| No.1 | Diamond wheel | Φ150*Φ12*6*8 100 mesh | Rough grinding |

| No.2 | Diamond wheel | Φ150*Φ12*6*8 180 mesh | |

| No.3 | Resin wheel | Φ130*Φ12*10*10 240 mesh | Arris grinding |

| No.4 | Fine grinding wheel 10S40 | Φ130*Φ60*35 mesh | |

| No.5 | Resin wheel | Φ130*Φ12*10*10 240 mesh | |

| No.6 | Fine grinding wheel 10S40 | Φ130*Φ60*35 mesh | |

| No.7 | Resin wheel | Φ150*Φ12*10*10 240 mesh | |

| No.8 | Fine grinding wheel 10S40 | Φ150*Φ70*30 mesh | |

| No.9 | Fine grinding wheel 10S60 | Φ150*Φ70*30 mesh | |

| No.10 | CE3/Wool felt | Φ150*Φ105*35 mesh | Flat edge polishing |

ZM10W glass straight-line efging machine parameter

| Type | ZM10W |

| Spindles QTY | 10 |

| Min. Glass size | 40*40mm |

| Processing glass thickness | 3-30mm |

| processing speed | 0.5-5m/min |

| Weight | about5500KGS |

| Installation power(kw) | 25kw |

| Occupied size(mm) | 7820*1400*2850mm |

| Arris | 45° |

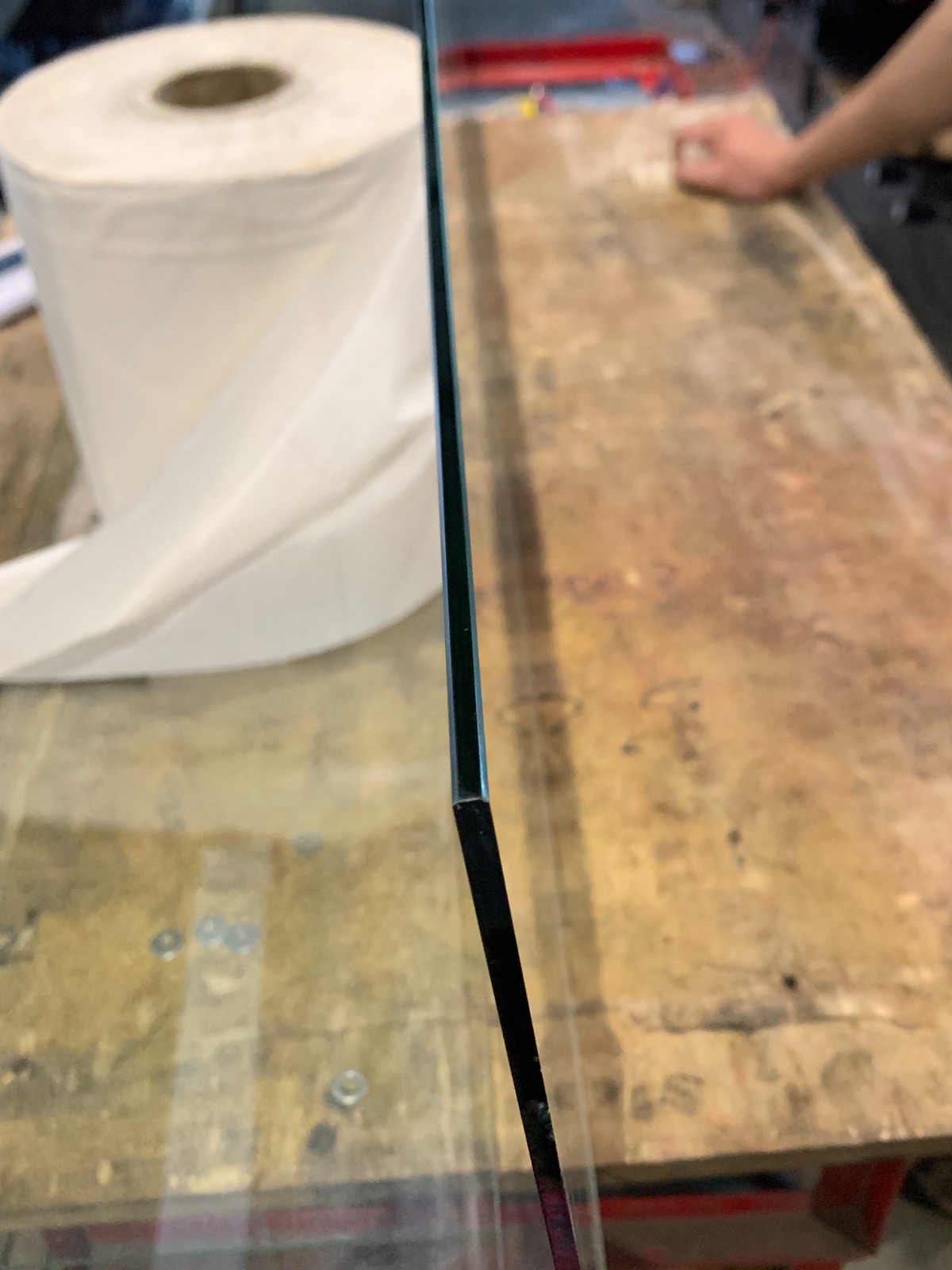

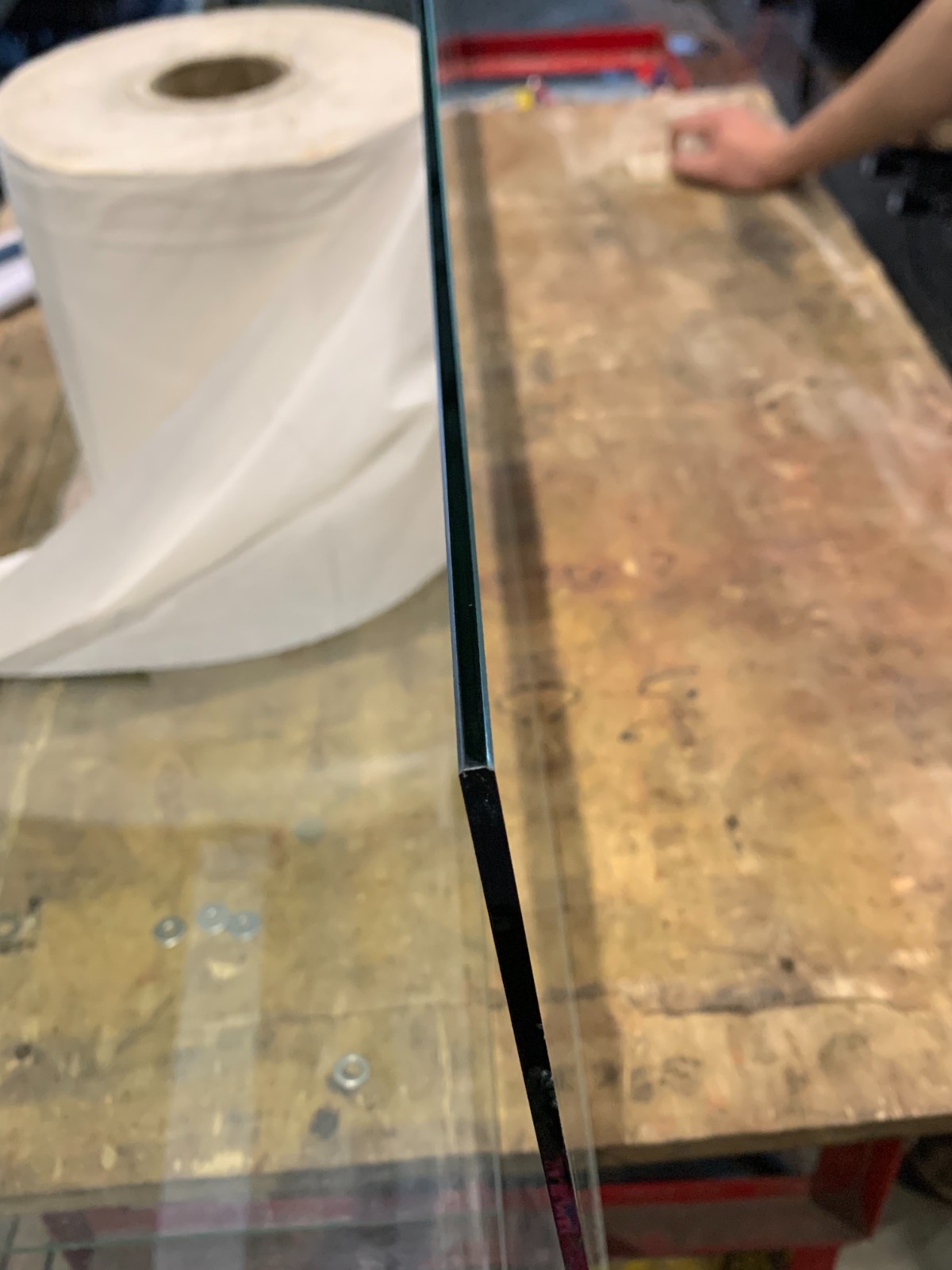

Glass samples

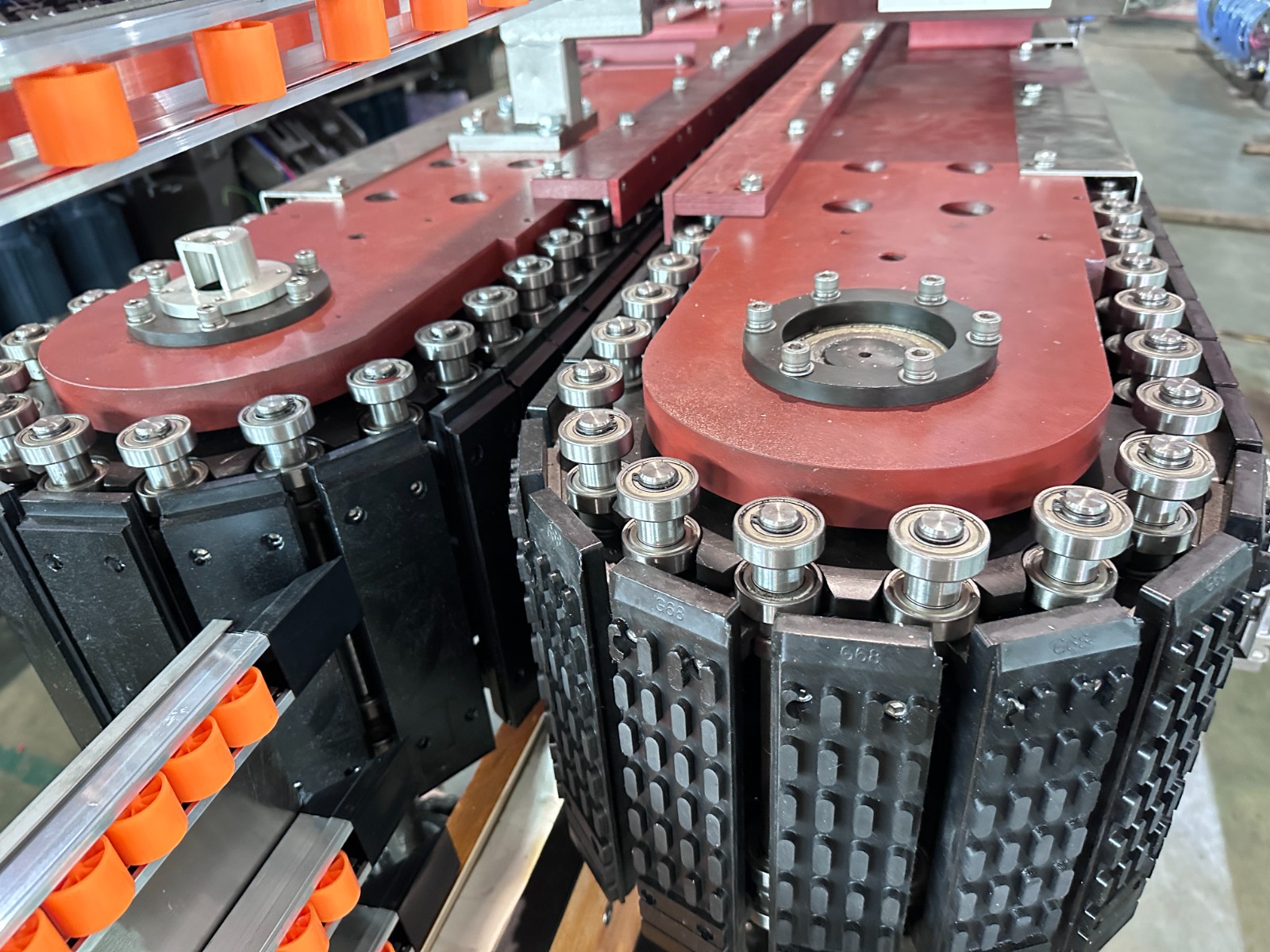

The front and rear reinforced casting beams, columns, and bases undergo secondary heat treatment, thereby bringing about a qualitative transformation in the welded parts. This not only enhances the hardness but also renders the machine more durable. The spare parts are processed by the CNC gantry machining center, reducing the cumulative tolerance of the entire assembly and enhancing the precision of edge grinding.

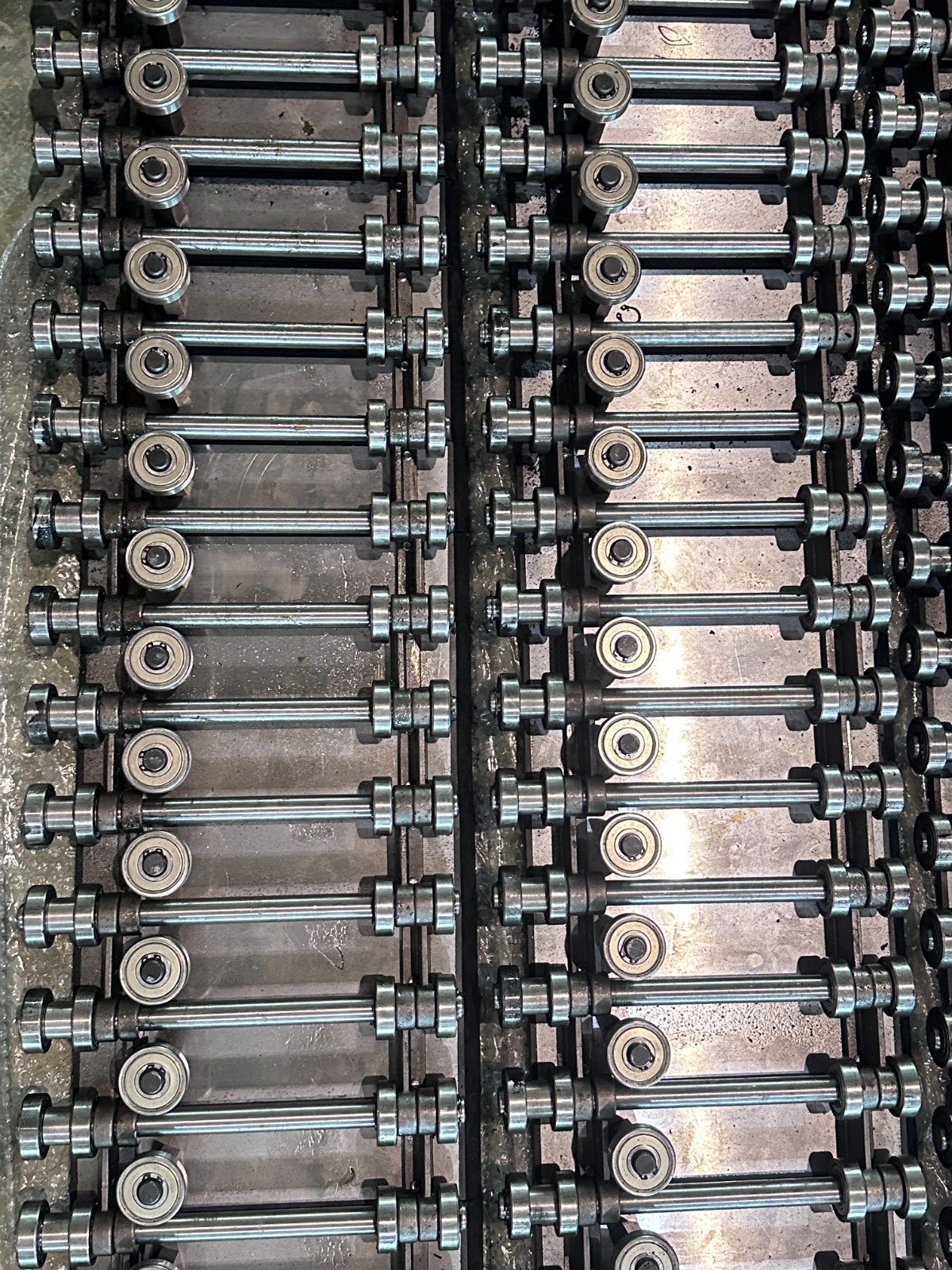

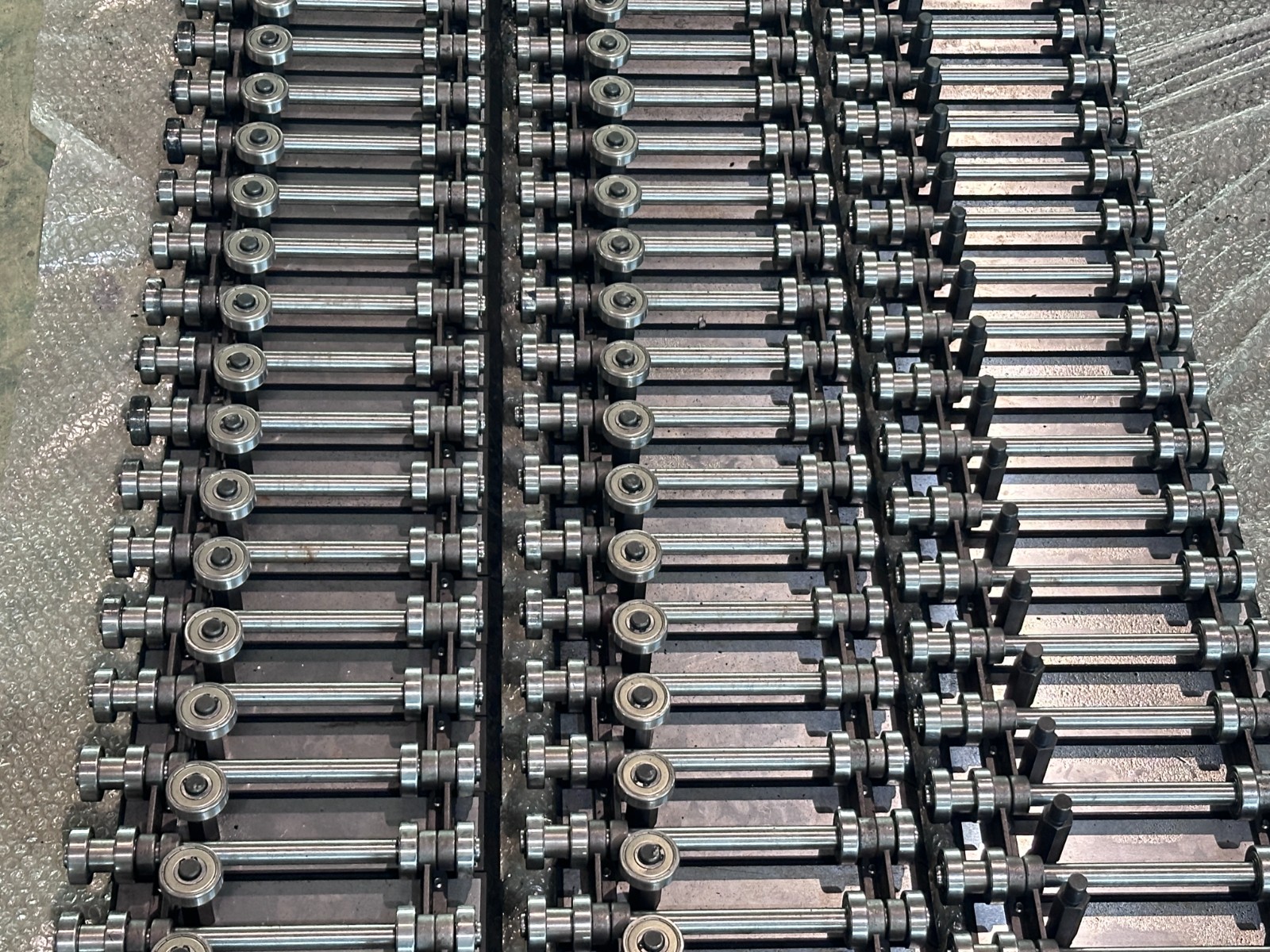

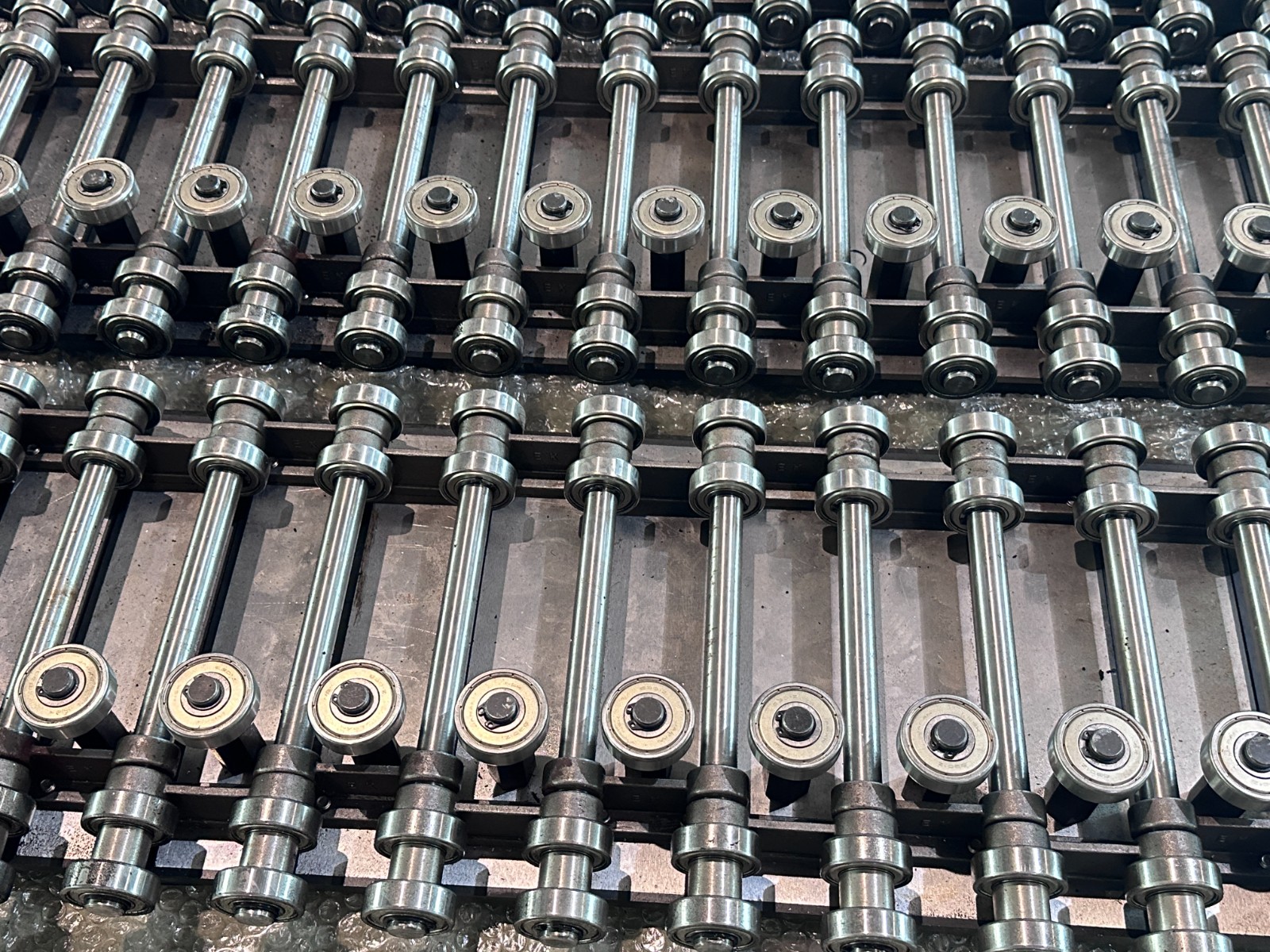

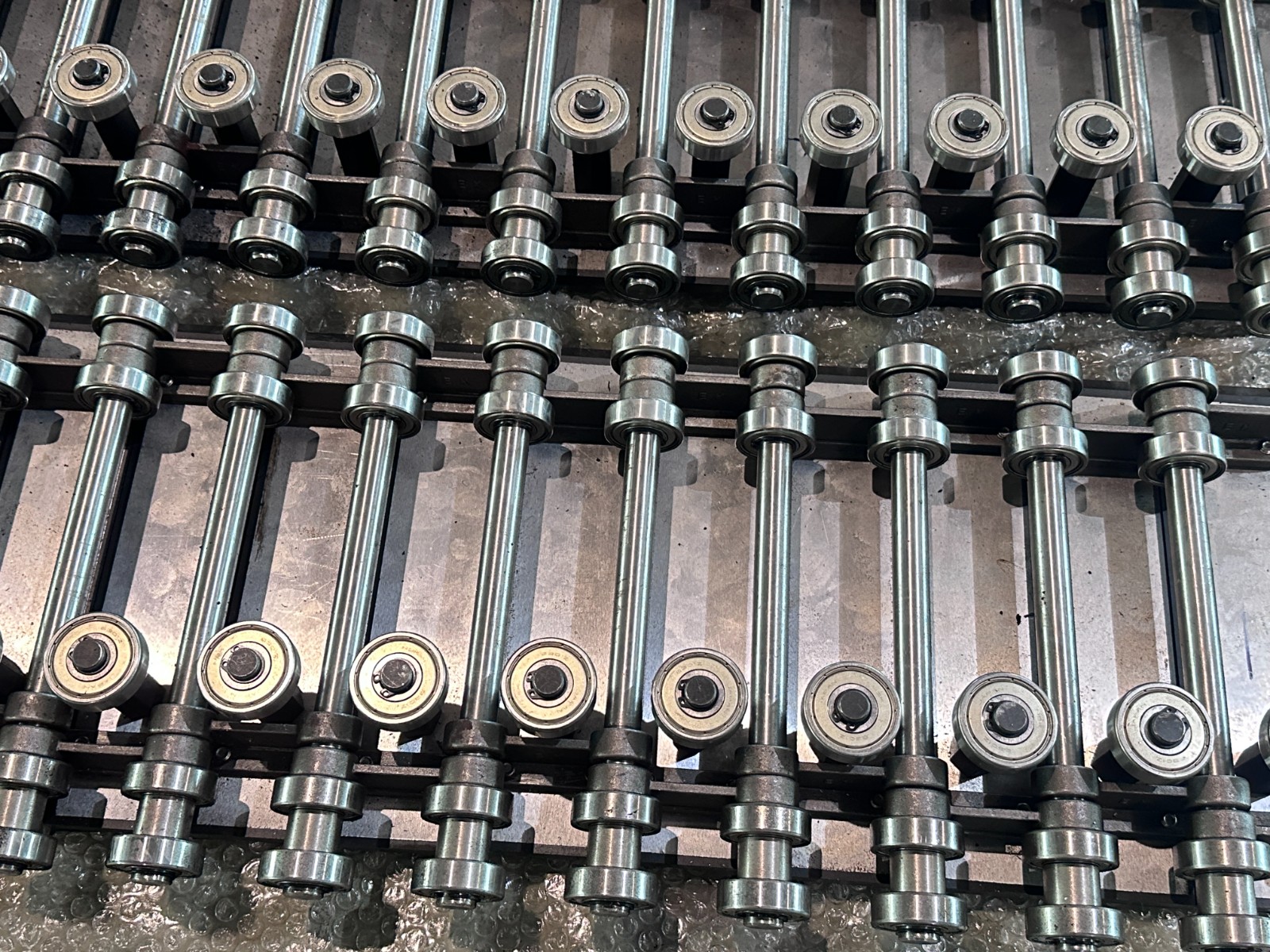

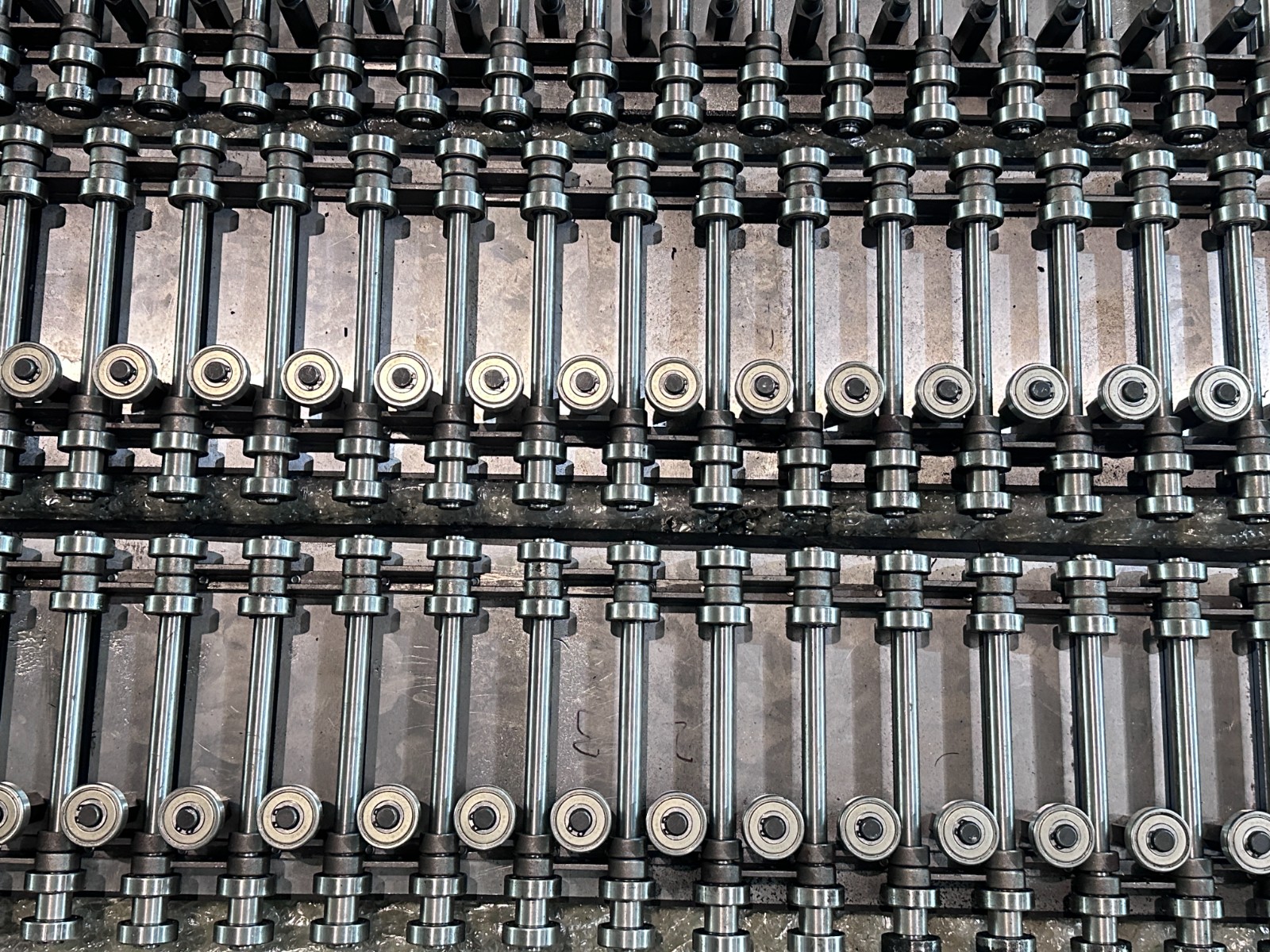

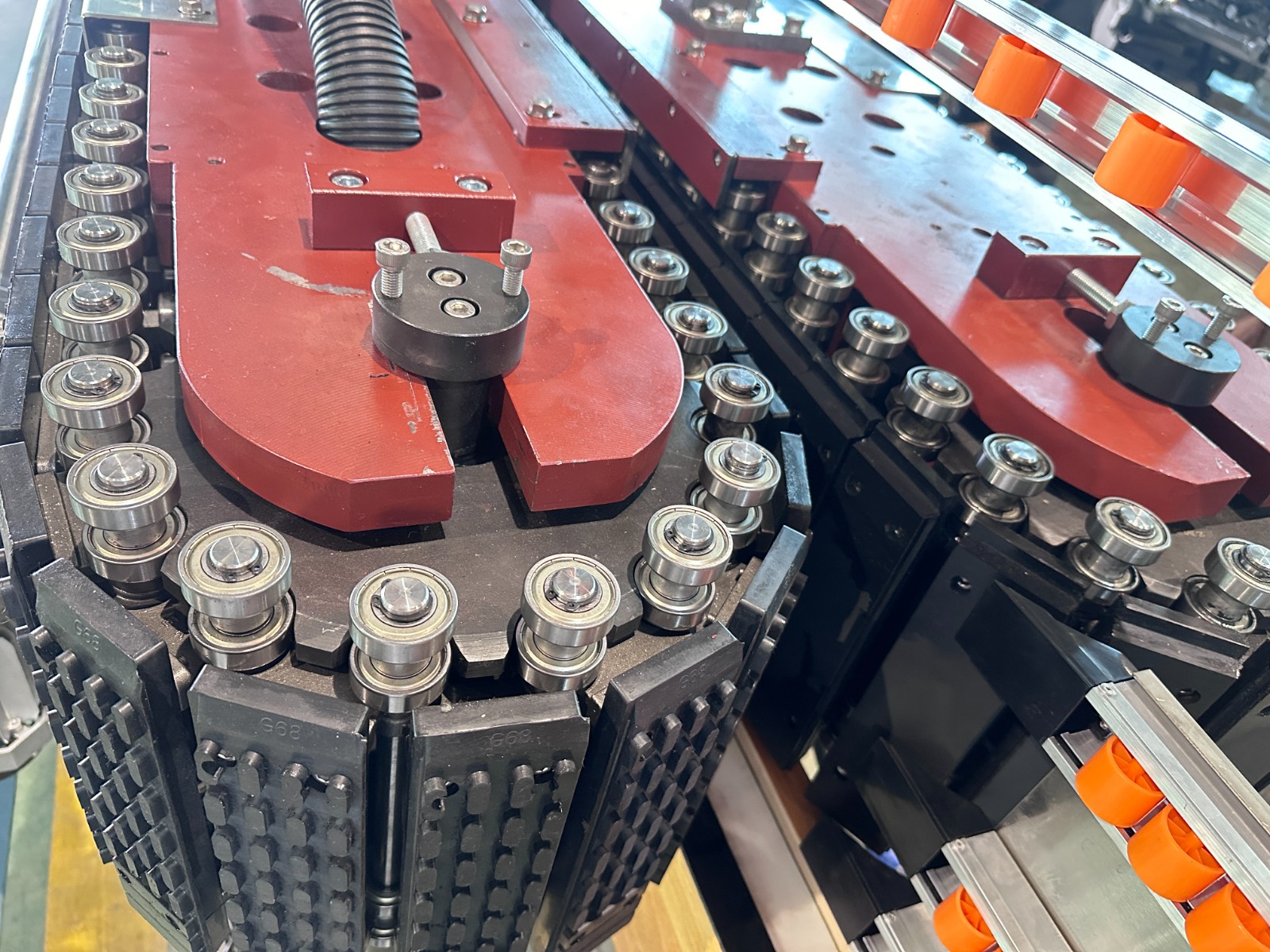

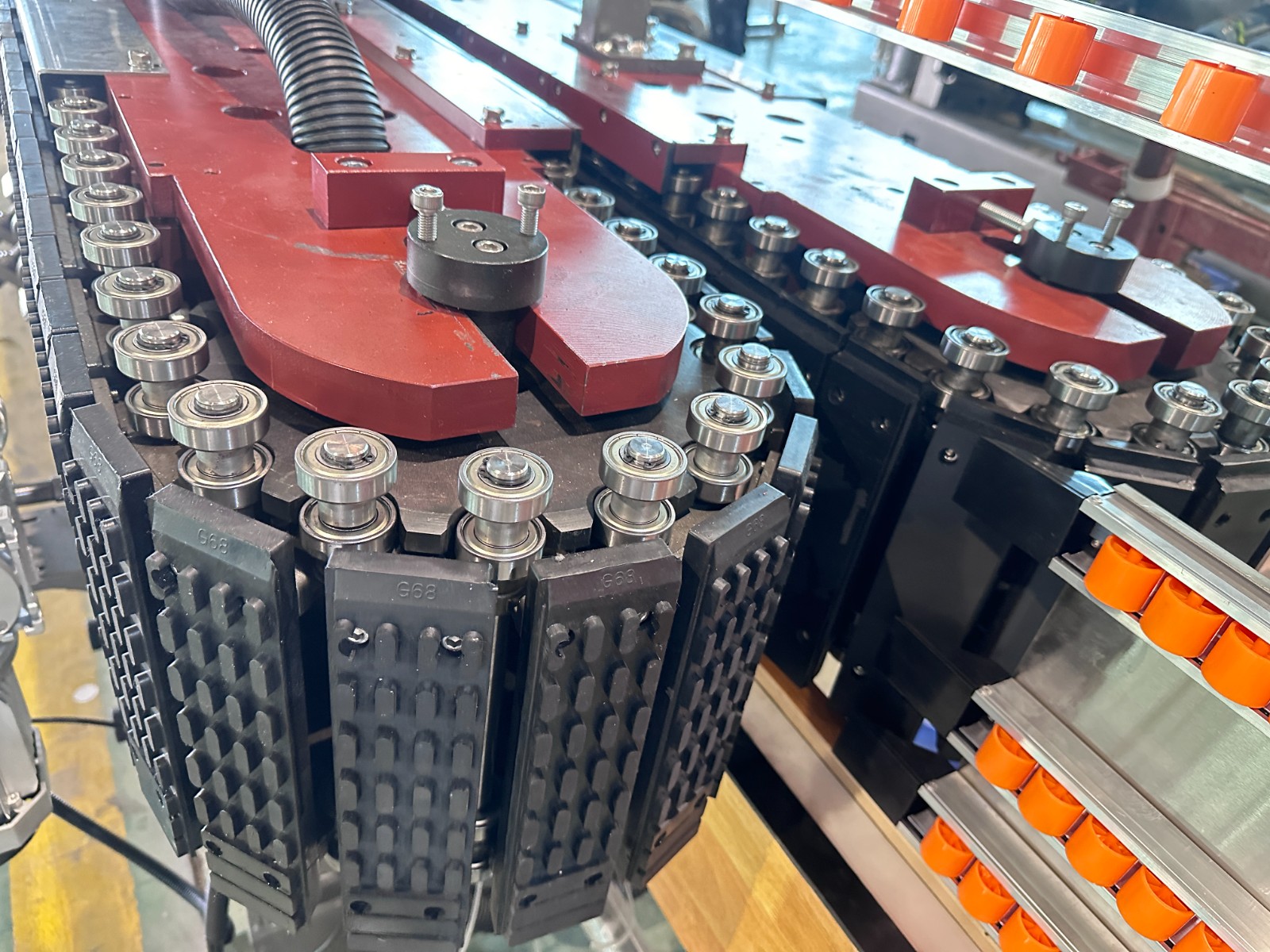

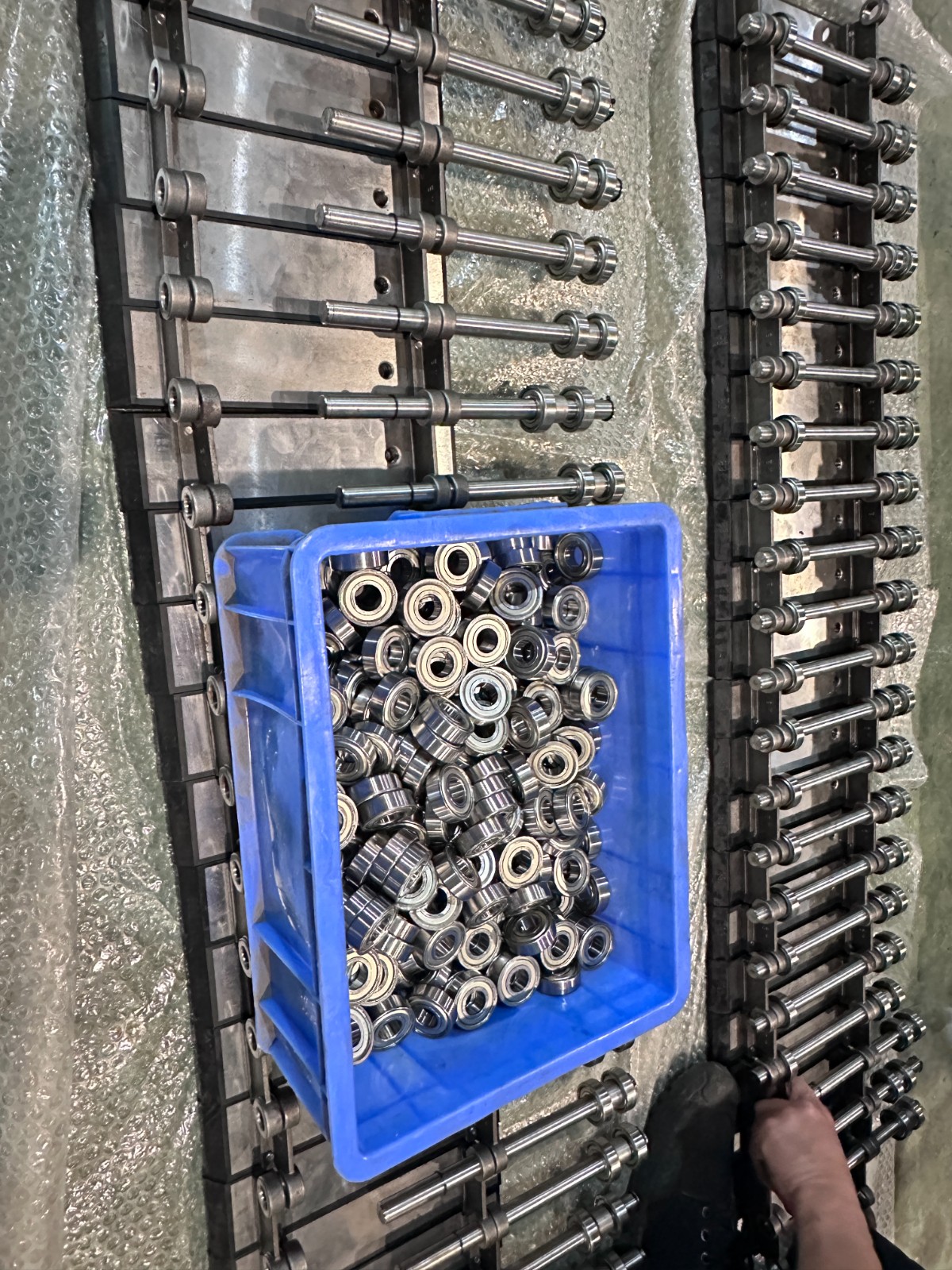

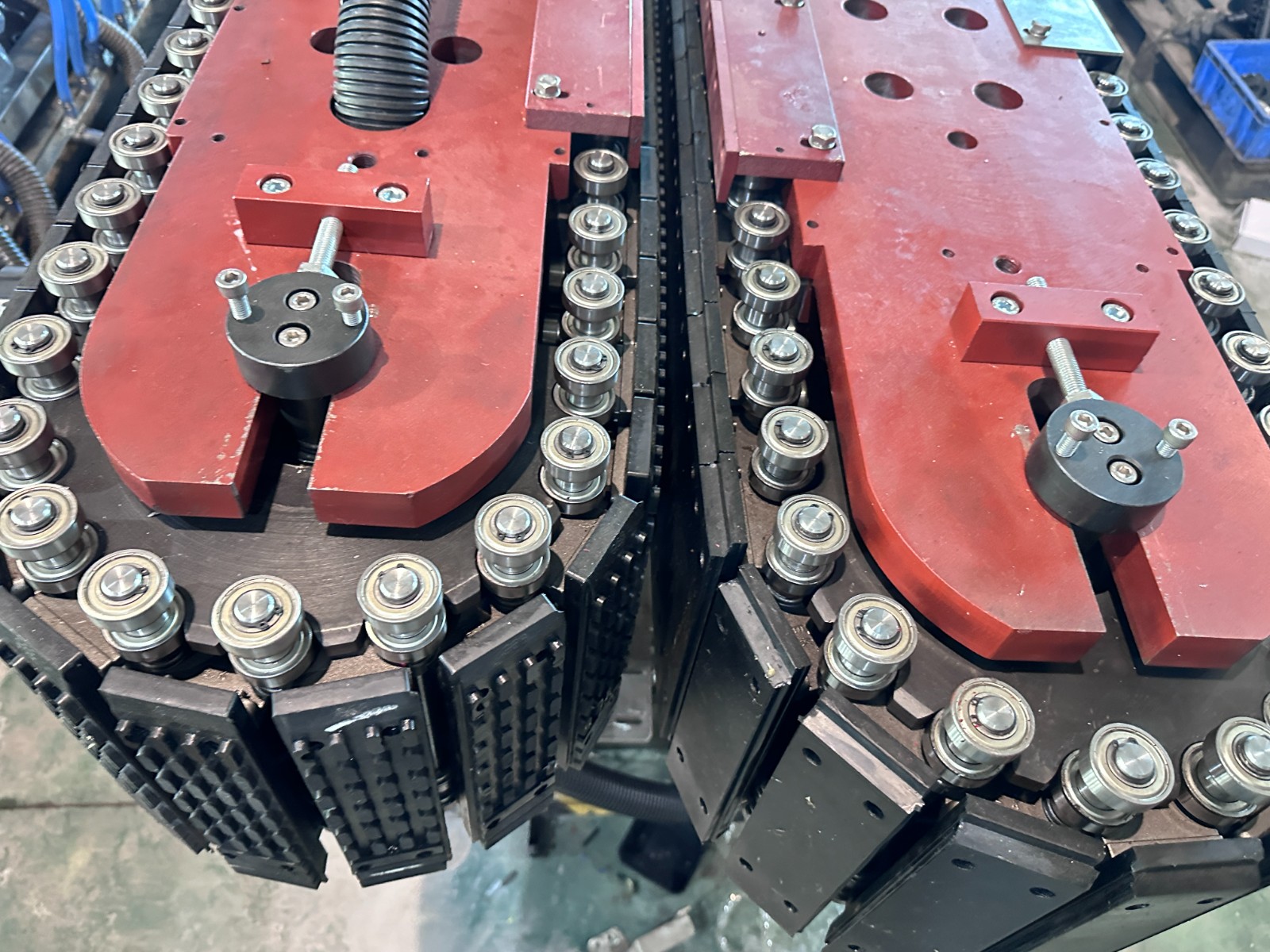

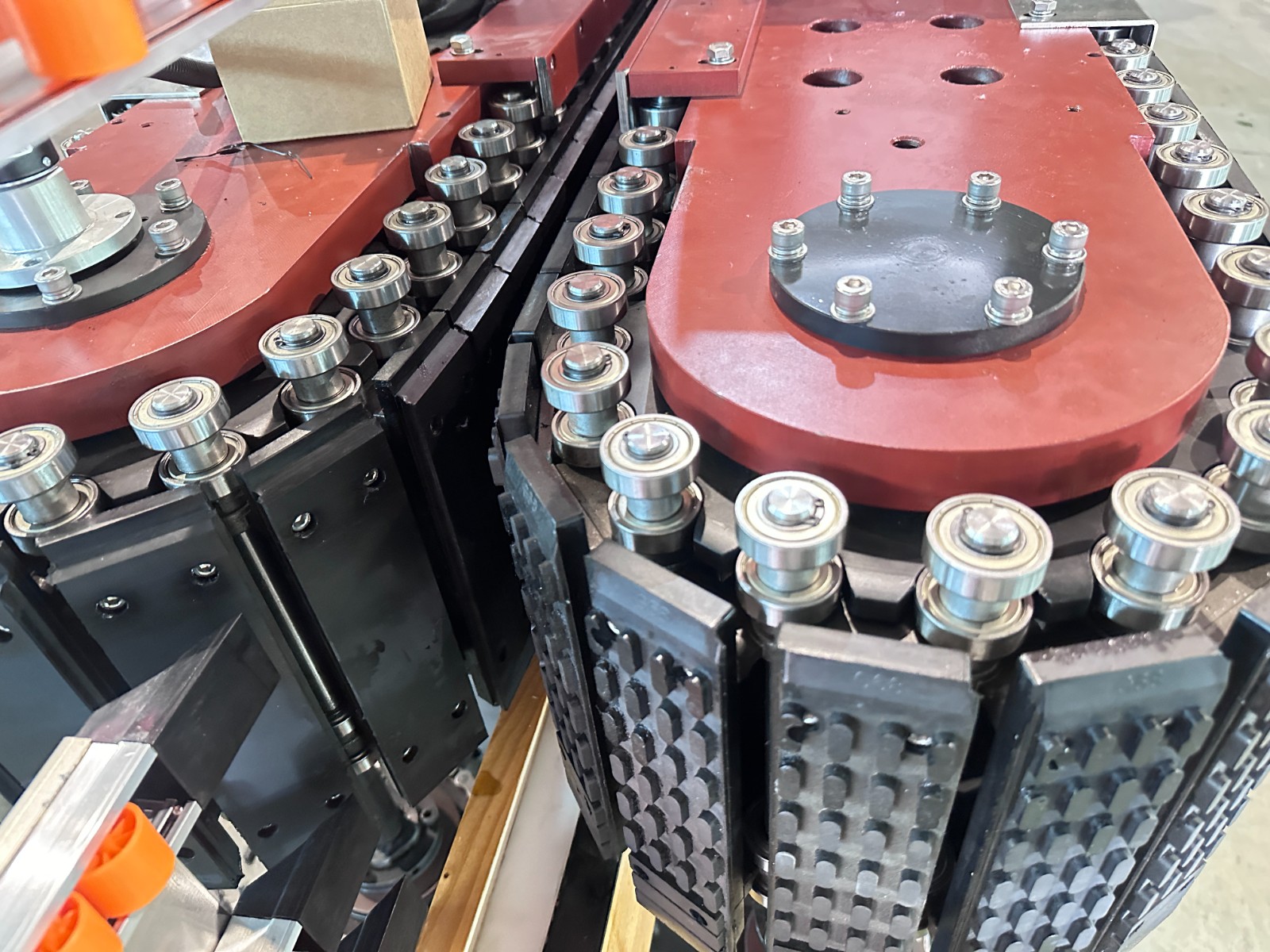

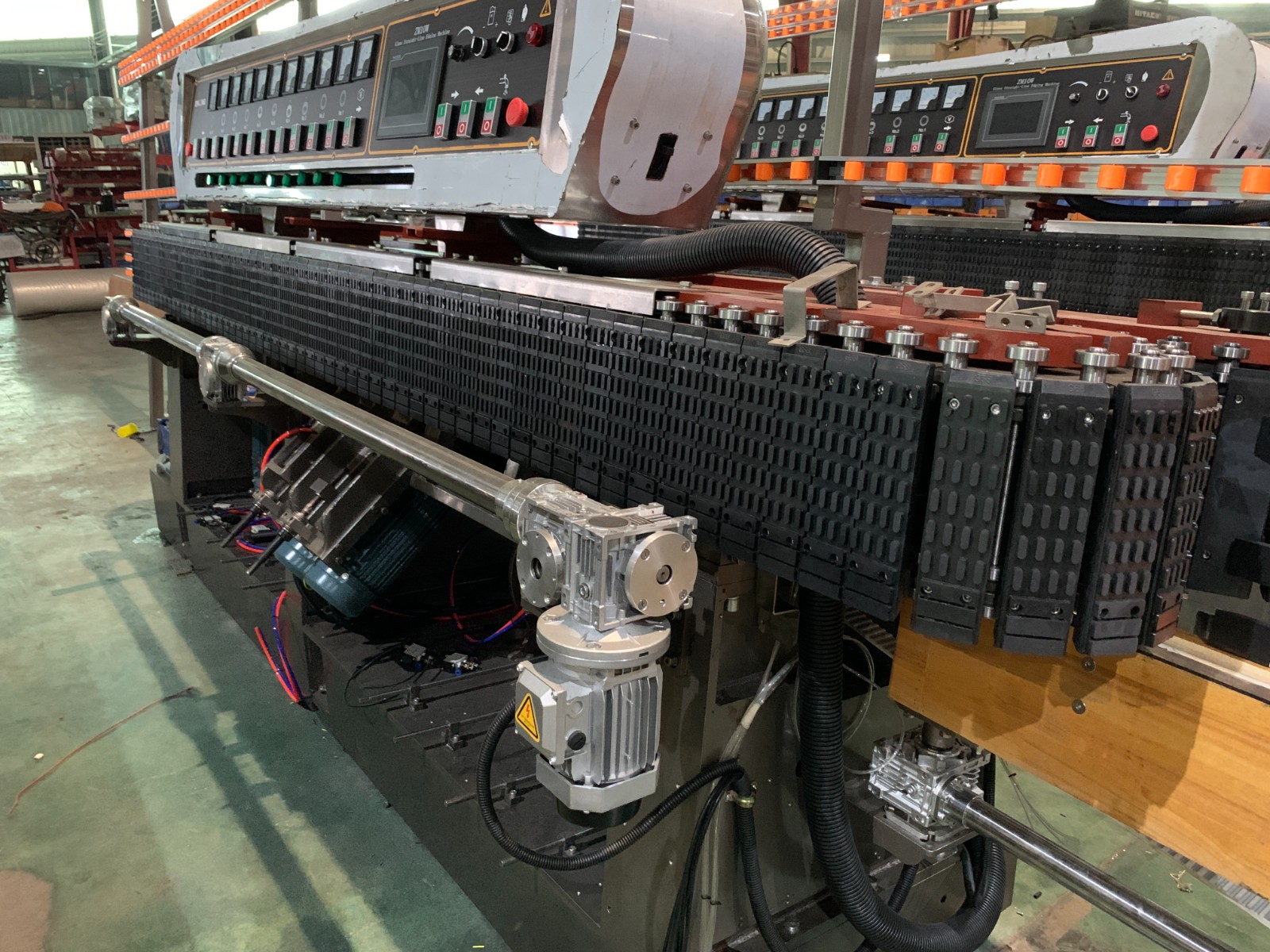

The conveying system adopts ball bearing units and a solid rectangular steel frame. This unique design enables the machine to possess an exceptionally strong bearing and conveying capacity. Specifically, it can withstand a load of up to 300 kgs per meter. It is capable of processing glass with a thickness ranging from 3 to 30 mm with remarkable precision. The chain plates are ingeniously structured to securely clamp the glass, thereby ensuring the accuracy of the glass diagonal. This advanced feature significantly enhances the reliability and efficiency of the processing operation, providing a stable and precise solution for glass processing needs.

Lifting structure for adjust the grinding amount of glass .easy to operate. With timing belt for loading glasses;

The processing speed controlled by Frequency motor and we have a separate frequency motor controls the timing belt speed to control processing speed.

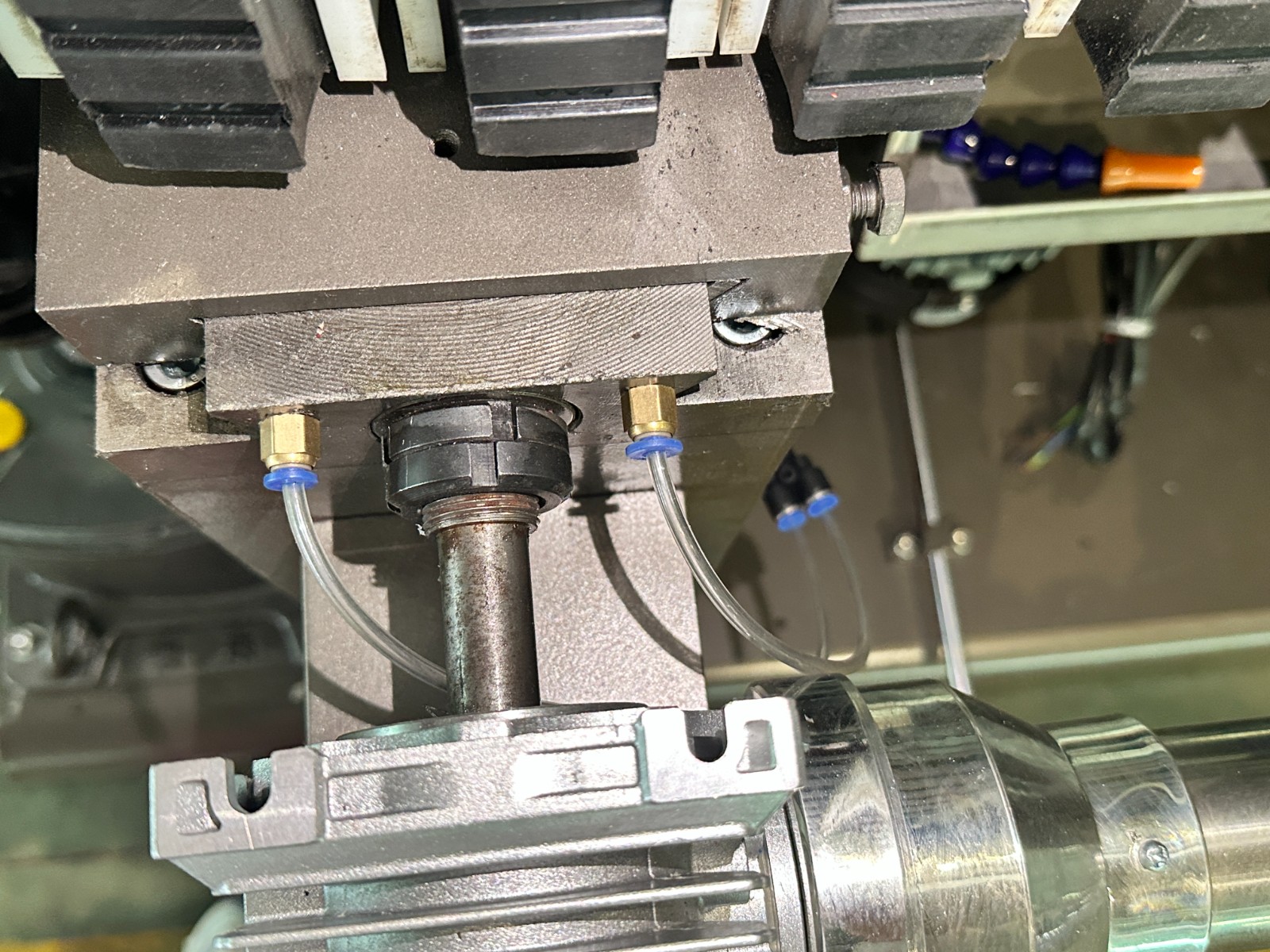

The combination of the cylinder and cross guide rail forms a flexible polishing, preventing the grinding head from sticking.

Lubrication system on every movements connections.

Using the CDQC grinding motors.

The water tank for wheels are uses stainless steel,stamped and formed, without welding, without cracks,

more waterproof and the surface is smooth; each wheel is equipment two pcs of water pipes for cooling;

The watering with two pcs of stainless steel water tanks. One is for clear water (No.1-8 wheels).

and the other one is for NO.10 (working with cerium)

The electrical elements using ABB /Schneider. The quality is reliable.

Adopt Schneider Electric PLC and touch screen you can input the parameter you need and machine will adjust automatically.

NO.4,6,8,9,10 will adopt the pneumatic polishing. The machine will showing the location of glasses during processing.