As rising sea levels and intensifying storms batter coastal urban centers, architects are racing to fortify skyscrapers with hurricane-proof glazing—a challenge that hinges on an unsung hero: glass grinding machines. By 2025, cities like Miami, Shanghai, and Rotterdam aim to enforce strict codes requiring laminated, edge-perfected glass for all coastal structures. But this raises a critical question: Can next-generation glass processing machines withstand the dual pressures of climate-driven demand and resource scarcity while maintaining surgical precision? From saltwater-resistant robotics to AI-optimized material usage, the industry’s response may redefine urban resilience.

The Storm-Proof Edge: How Glass Grinding Machines Are Reinventing Coastal Architecture

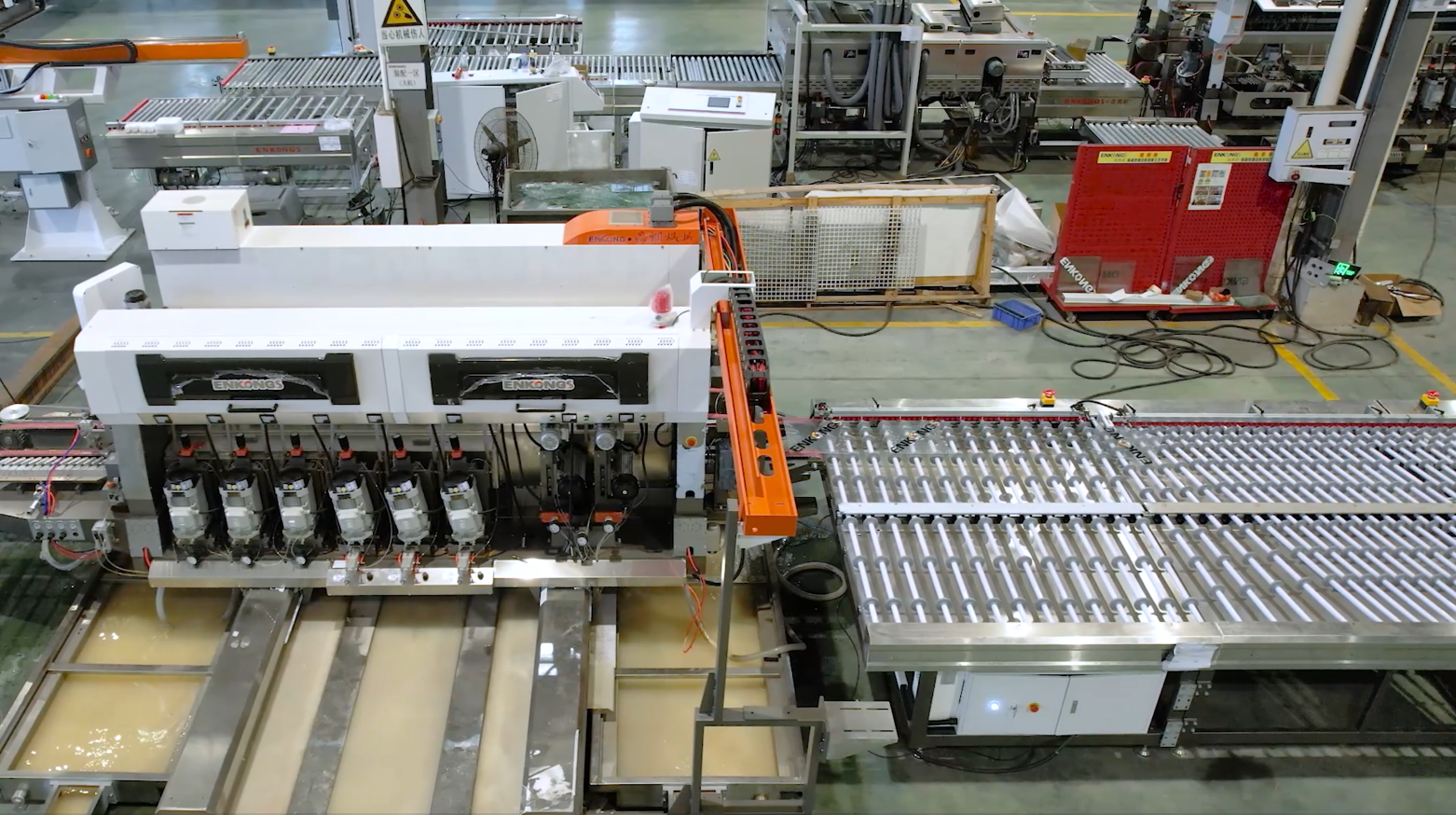

Hurricane-grade glass isn’t just about thickness—it’s about edges. A poorly ground edge creates stress points that can shatter entire panels under 150 mph winds. Traditional glass edging machines, however, struggle with the unique demands of laminated glass layers. "Post-2025 building codes demand edges polished to 0.05mm uniformity," states Hiroshi Tanaka, lead engineer at Tokyo’s Disaster-Proof Glass Initiative. "Anything less is a liability."

Enter climate-adaptive glass grinding machines. These systems use diamond-tipped abrasives cooled by desalinated seawater, preventing corrosion in coastal factories. A pilot project in New Orleans saw a 60% drop in post-storm glass replacements after adopting humidity-resistant glass processing machines. "The machine doesn’t just grind; it anticipates," says engineer Leila Carter. "It adjusts grinding speed based on real-time weather data fed from NOAA satellites."

Sand Scarcity Solutions: Can Glass Processing Machines Turn Desert Dust into Building Materials?

Global sand reserves—the primary component of glass—are dwindling, with UNEP warning of a "sand crisis" by 2030. Conventional glass grinding machines waste 18% of raw sand during processing, but 2025’s models are mining innovation from unexpected sources.

Sahara Glassworks, a Moroccan startup, now feeds its glass edging machines with silica extracted from desert dust. Their patented process uses AI to sort and purify sand particles as fine as 0.1mm, which older glass grinding machines would reject as unusable. Meanwhile, their glass processing machines recycle 99% of cooling water via solar-powered desalination. "We’re literally turning sandstorms into skyscrapers," boasts CEO Youssef Al-Mansoori.

The Arctic Challenge: Glass Edging Machines in -60°C Frontier Construction

As polar ice retreats, cities like Norilsk and Nuuk are expanding—but extreme cold brittles glass, making edge flaws catastrophic. Standard glass grinding machines falter in subzero temperatures, where lubricants freeze and metal parts contract.

Swedish firm FrostGlass’s answer? A glass processing machine with heated grinding beds and graphene-reinforced diamond wheels that thrive at -70°C. Deployed in Siberia’s new Arctic research hub, these glass edging machines maintain 0.1mm precision while operating on geothermal energy. "The machine’s exhaust heat melts ice for drinking water," notes project lead Ingrid Bergström. "It’s a closed-loop system for the harshest environments."

Bioluminescent Edges: When Glass Grinding Machines Meet Synthetic Biology

What if glass edges could glow? MIT’s Media Lab and Boston-based BioGlaziers are embedding bioluminescent algae into glass panels during the grinding phase. Specialized glass edging machines inject algae colonies into micro-channels carved along edges, creating self-illuminating safety rails for blackout-prone areas.

"The glass grinding machine must polish without killing the organisms," explains synthetic biologist Dr. Priya Rao. "Our machines use UV-free lasers and nutrient-infused coolants." Early trials in Oslo’s pedestrian tunnels reduced lighting energy costs by 90%. Critics question scalability, but 2025’s bio-hybrid glass processing machines already attract disaster-response agencies.

The Space Race Overhead: Glass Edging Machines for Orbital Solar Farms

With the ESA and NASA planning orbital solar farms by the 2030s, manufacturers face an extraterrestrial challenge: grinding glass in zero gravity. Earth-bound glass processing machines rely on gravity to manage debris and coolant flow—a system doomed in space.

Lockheed Martin’s prototype "Orbital Edge" glass edging machine uses electromagnetic fields to control grinding dust and ionized water jets that self-contain in vacuum conditions. Tested aboard the ISS, it achieved mirror-grade edges on silica panels critical for concentrating sunlight. "It’s not just about precision," says aerospace engineer Carlos Mendez. "These glass grinding machines must survive radiation storms and micrometeoroid strikes."

The Counterfeit Crisis: AI Glass Grinding Machines as Forgery Fighters

Luxury brands like Louis Vuitton and Tiffany now embed NFC chips into glass packaging—but counterfeiters replicate these with alarming accuracy. Enter authentication-focused glass edging machines.

Parisian security firm VerreSecur’s machines grind microscopic fractal patterns into glass surfaces, readable only by quantum sensors. Each pattern is unique, generated in real time by AI algorithms during grinding. "A counterfeit bottle would require replicating 10,000 nanoscale edge variations," says CTO Élodie Rousseau. "Even our own glass processing machines can’t duplicate a pattern twice."

The Refugee Camp Revolution: Portable Glass Grinding Machines for Crisis Zones

When Medecins Sans Frontieres needed hurricane-proof mobile clinics in Bangladesh’s floodplains, they turned to a unlikely solution: shipping-container-mounted glass processing machines. Dutch NGO GlassAid’s portable units grind recycled bottle glass into storm-resistant window panels onsite.

"Each machine fits in a pickup bed and runs on pedal power if needed," says field coordinator Lars van Dijk. Refugee artisans trained in 48 hours now produce 200 panels daily. The design has spread to wildfire zones in California and Australia, where mobile glass edging machines turn debris into rebuilding materials.

The Invisible Threat: Glass Grinding Machines vs. Microplastic Pollution

A 2024 study revealed that traditional glass edging machines generate 2.3 million tons of microplastic-like silica dust annually—particles small enough to enter bloodstreams. EU regulators are drafting 2025 bans on machines exceeding 0.01mg/m³ emissions.

Austrian manufacturer CleanGrind responded with a closed-loop glass processing machine that vacuums and vitrifies dust into solid tiles mid-operation. Hospitals in Vienna now use these tiles for antibacterial flooring. "Our machine’s byproduct is literally cleaner than urban air," claims CEO Felix Gruber.

The Cultural Reckoning: Indigenous Glass Edging Techniques Reshaping Modern Machines

When Canadian First Nations communities protested a lithium mine threatening ancestral quartz deposits, engineers found common ground. The Tl’chés tribe’s 10,000-year-old stone-grinding methods inspired a new glass edging machine that mimics the "pulsing" motion of hand-polishing sacred artifacts.

Vancouver-based TriboTech’s machines reduce energy use by 70% compared to industrial grinders. "The rhythm matters," explains elder-turned-consultant Kwanlin Dün. "Fast grinding cracks the spirit of the glass." Luxury brands now pay premiums for "culturally resonant" edges, funding indigenous land preservation.

The 2025 Horizon

From hurricane alleys to orbital frontiers, glass edging machines are no longer mere factory tools—they’re climate warriors, cultural bridges, and lifelines for marginalized economies. As 2025’s deadlines loom, one truth emerges: The machines smoothing today’s glass edges are sharpening humanity’s capacity to adapt, create, and endure. The question isn’t whether glass processing machines will evolve, but whether our vision for their potential can keep pace.