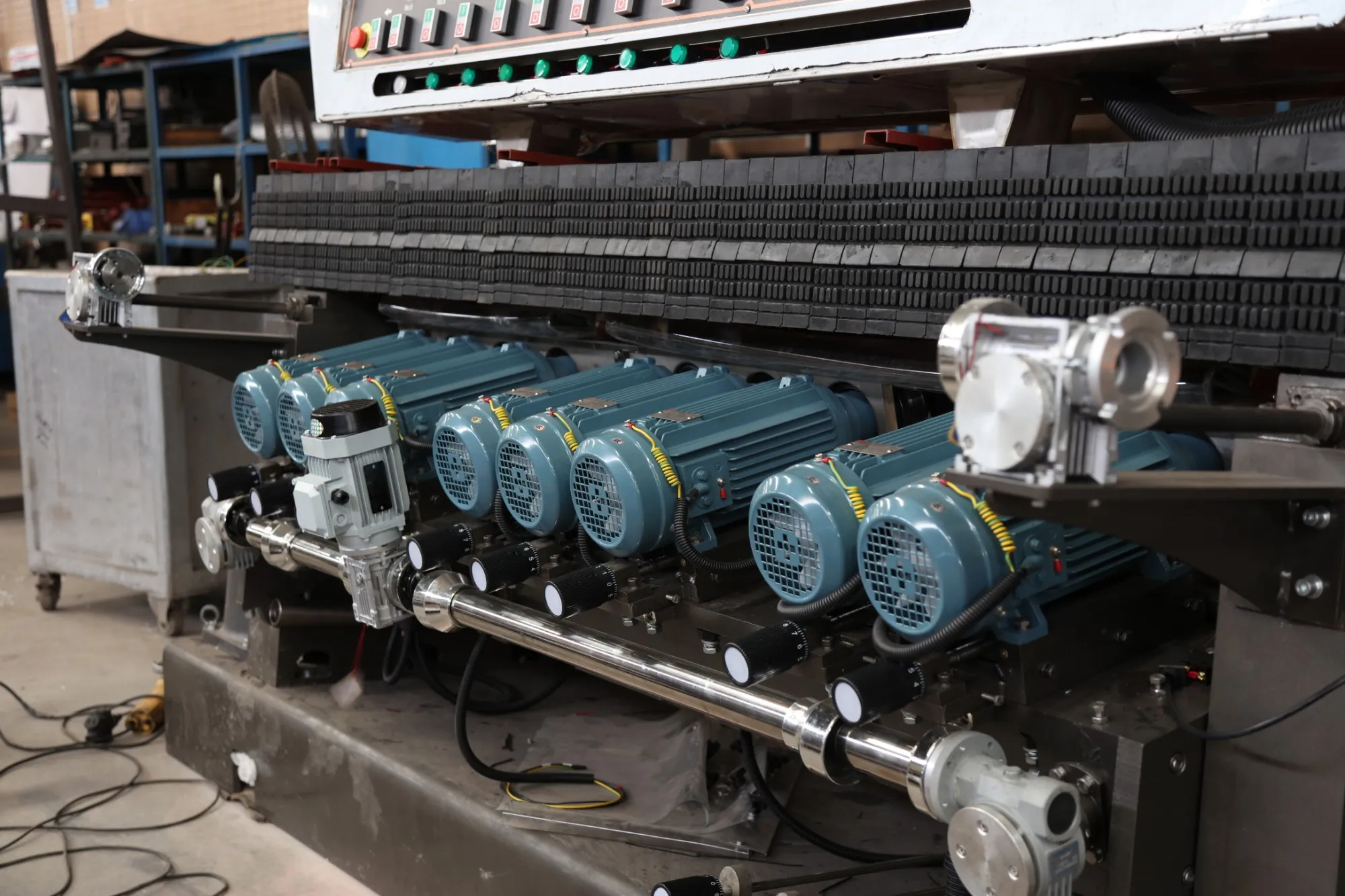

XM351 glass beveling machine is convenient to change and adjust the overall advance and retreat of the grinding head, the angle of the slope, and the thickness of the glass. Flat glass of the same thickness can be processed continuously, and the polished slope is close to the finish of the glass matrix. WhatsAPP+86 188 2308 1140 Email:jmek@enkongs.net

The pursuit of perfection in glass fabrication has lengthy been focused at the nice of the part. While directly sharpening stays fundamental, the cappotential to create flawless, regular bevels has emerge as a trademark of high-give up craftsmanship, commencing doorways to architectural elegance, state-of-the-art furniture, and ornamental art. This specialised phase of the marketplace is pushed through a trio of interconnected but awesome technologies: the versatile glass beveling edging machine, the finishing-focused glass bevel edge polishing machine, and the precision-oriented glass straight-line beveling machine. Together, those superior structures empower fabricators to convert easy glass sheets into delicate merchandise with better visible intensity and safety. The evolution of this generation marks a sizable shift from labor-in depth guide strategies to automated, repeatable precision, making sure that complicated part profiles are now not a luxurious however an reachable standard.

At the middle of making an angled part is the glass beveling edging machine. This class of system is designed for the number one mission of grinding the preferred bevel attitude onto the glass substrate. Modern variations of the glass beveling edging machine are exceedingly state-of-the-art, presenting programmable settings for attitude width and intensity, regularly managed thru intuitive virtual interfaces. The robustness of a terrific glass beveling edging machine lets in it to address the preliminary tough grinding section with effective cars and coarse diamond wheels, correctly shaping the glass with out inflicting chips or cracks. The precision executed at this level is critical, because it units the muse for the very last end. While a glass straight-line beveling machine is a particular kind inside this class, the wider time period glass beveling edging machine also can embody machines able to curved bevels, aleven though linear packages are maximum not unusualplace for architectural and indoors layout projects. The performance of this preliminary shaping technique immediately affects the workload of the following glass bevel edge polishing machine.

Once the bevel attitude is as it should be floor, the point of interest shifts to reaching optical readability and a smooth, reflective floor. This is the exceptional area of the glass bevel edge polishing machine. This gadget is engineered with a sequence of step by step finer sharpening heads, regularly using felt or resin bonds with diamond or cerium oxide sharpening compounds. The number one goal of the glass bevel edge polishing machine is to convert the matte, floor floor left through the glass beveling edging machine right into a brilliant, crystal-clean end that complements the light-refracting houses of the glass. The sophistication of a present day glass bevel part sharpening gadget lies in its cappotential to hold regular strain and call throughout the complete angled floor, a project that less complicated machines can't meet. For lengthy, uninterrupted edges, feeding the glass thru a glass straight-line beveling machine that integrates a complete sharpening line is the maximum green method, making sure uniformity from begin to end.

For tasks requiring long, flawlessly regular bevels on panels for windows, doors, or desk tops, the glass straight-line beveling machine is the most efficient solution. This gadget is a specialised subset of the wider glass beveling edging machine family, designed particularly for processing the instantly edges of flat glass sheets with unheard of accuracy. The glass straight-line beveling machine commonly carries a inflexible linear manual gadget that guarantees the grinding and sharpening heads tour in a perfectly instantly path, casting off any wavering or deviation withinside the bevel profile. This stage of precision is tough to acquire with a greater general-cause glass beveling edging machine. Many superior fashions of the glass straight-line beveling machine feature as included structures, combining the grinding functionality of a number one glass beveling edging machine with the completing energy of a glass bevel edge polishing machine in a single, computerized pass, dramatically decreasing processing time and handling.

The integration of automation and clever generation has revolutionized all 3 gadget types. A cutting-edge glass beveling edging gadget regularly capabilities automated wheel put on compensation, making sure the bevel dimensions stay regular whilst the diamond grinding wheels step by step diminish. Similarly, a high-quit glass bevel edge polishing machine would possibly encompass programmable stress manage for exceptional sharpening stages, optimizing the end for diverse glass types, from general waft glass to sensitive tempered glass. The glass straight-line beveling machine advantages immensely from those advancements, with CNC structures storing loads of recipes for exceptional bevel angles and lengths, permitting for fast activity changeovers with ideal repeatability. This virtual spine connects the capability of the glass beveling edging machine and the glass bevel edge polishing machine, developing a continuing manufacturing flow.

The financial effect of making an investment on this specialised beveling generation is substantial. For a fabrication shop, proudly owning a dependable glass beveling edging machine and a excellent glass bevel edge polishing machine unlocks get right of entry to to higher-margin tasks in residential and industrial interiors. The capacity to provide an ideal bevel in-residence reduces reliance on third-birthday birthday celebration processors and shortens lead times. The throughput and consistency provided via way of means of an automatic glass straight-line beveling machine make it vital for groups that specialize in extent manufacturing of beveled glass products, along with reflect producers or cupboard door suppliers. The aggregate of those technology correctly future-proofs a business, permitting it to compete withinside the top rate section of the glass market.

In conclusion, the synergistic dating among the glass beveling edging machine, the glass bevel edge polishing machine, and the glass straight-line beveling machine represents the slicing fringe of ornamental glass processing. This trio of era permits fabricators to always acquire what become as soon as the reserve of grasp craftsmen: a flawless, light-catching bevel that provides giant fee and splendor to any glass product. As call for for custom designed and high-layout glass factors keeps to grow, the function of those precise, efficient, and automatic machines will best grow to be extra vital to the achievement and innovation inside the international glass industry.