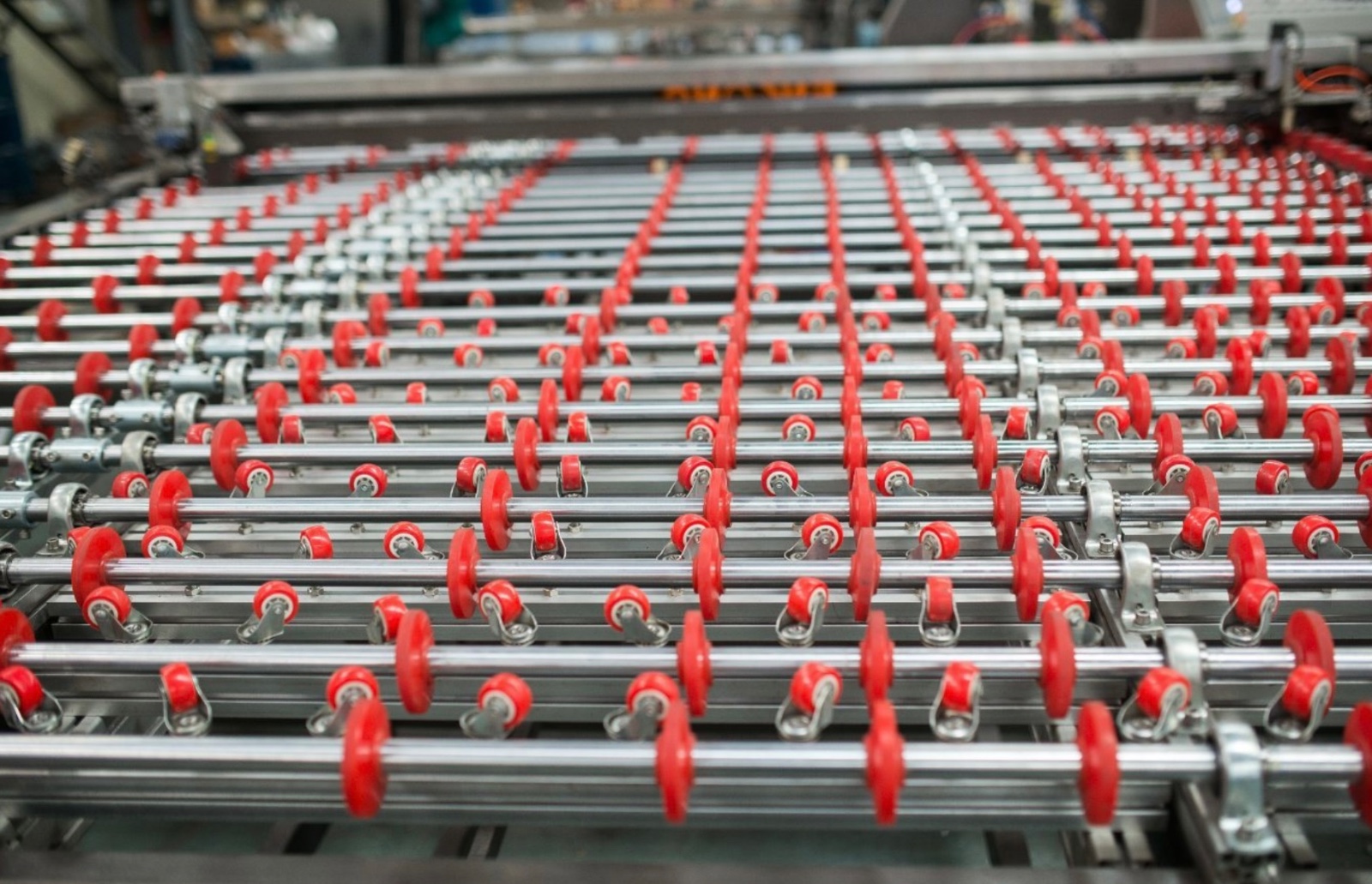

The glass detecting table surface itself is designed to support the glass sheet securely while minimizing interference with the inspection process. The glass processing machine is typically made of a smooth, flat material such as tempered glass, acrylic, or a non-reflective metal. In some cases, glass processing machine may include air bearings or vacuum systems to hold the glass in place without causing scratches, especially for large or delicate glass sheets.

1.Lighting Systems

As mentioned earlier, lighting systems are critical. The glass processing machine include LED arrays, fluorescent lamps, or laser diodes, chosen for their stability, brightness, and ability to produce consistent light. The glass grinding machine is often adjustable in intensity, angle, and color temperature to optimize defect visibility for different glass types (e.g., clear, tinted, or coated glass).

2.Imaging Devices

High-resolution cameras (CCD or CMOS) are used to capture images of the glass surface. The number of cameras depends on the table size and inspection requirements—larger glass sheets may require multiple cameras to cover the entire surface. Some systems also use line scan cameras, which capture images in a continuous line as the glass moves, ideal for high-speed inspection of large sheets.

3Computer Vision and Software

The "brain" of the system, computer vision software processes the images captured by the cameras. It uses machine learning or predefined algorithms to analyze pixel data, detect defects, and classify them.

These are basic tables where operators visually inspect glass sheets under controlled lighting. They may include tools such as magnifying glasses or rulers to measure defects. Manual tables are cost-effective but rely on operator skill and attention, making them prone to human error. They are typically used in small-scale operations or for low-volume, high-precision inspection tasks.

4.Semi-Automatic Glass Detecting Tables

Semi-automatic tables combine manual and automated elements. For example, the glass grinding machine may automatically illuminate the glass grinding machine and capture images, but operators review the images to confirm defects. This type balances cost and accuracy, suitable for medium-scale production where some human oversight is still needed.

5.Fully Automatic Glass Detecting Tables

Fully automatic tables handle the entire inspection process without manual intervention. They integrate with production lines, automatically feeding, inspecting, and sorting glass sheets. These systems use advanced computer vision and machine learning to detect defects with high accuracy, making them ideal for large-scale manufacturing facilities producing glass for critical applications (e.g., automotive windshields or architectural safety glass).

Glass used in electronics (e.g., smartphone screens, LCD panels, or touchscreens) requires extreme precision. Micro-scratches, bubbles, or inclusions can affect functionality or display quality. Detecting tables with high-resolution cameras and sensitive algorithms are used to identify these tiny defects, ensuring reliable electronic devices.

6.Furniture and Decorative Glass

For glass tabletops, mirrors, or decorative panels, defects such as scratches or uneven edges reduce aesthetic appeal. Detecting tables help manufacturers maintain a high standard of finish, ensuring the glass meets customer expectations for beauty and durability.

7.Solar Panel Glass

Solar panels rely on clear, defect-free glass to maximize light transmission and energy efficiency. Detecting tables inspect for bubbles, inclusions, or coating defects that could block sunlight or reduce panel performance, contributing to more efficient renewable energy systems.

Despite their advantages, glass detecting tables face certain challenges:8.Detection of Subtle Defects

Some defects—such as very small bubbles or shallow scratches—may be difficult to detect, especially in thick or tinted glass. This requires continuous improvement in camera resolution and algorithm sensitivity.

8.False Detections

Factors like dust, fingerprints, or variations in glass thickness can trigger false defect alerts, requiring operators to verify results or for algorithms to be fine-tuned for specific glass types.

9.Cost of Advanced Systems

Fully automatic, high-precision detecting tables are expensive, making them less accessible for small manufacturers. However, the long-term cost savings from improved quality often justify the investment for larger operations.

10.Handling Delicate Glass

Thin or fragile glass sheets can be damaged during transport or inspection, requiring specialized handling systems (e.g., vacuum lifts or air cushions) that add complexity and cost.

11.Future Trends in Glass Detecting Tables

The future of glass detecting tables is shaped by advancements in technology, aiming to enhance accuracy, speed, and versatility: