GUANGDONG ENKONGS MACHINERY CO.,LTD.

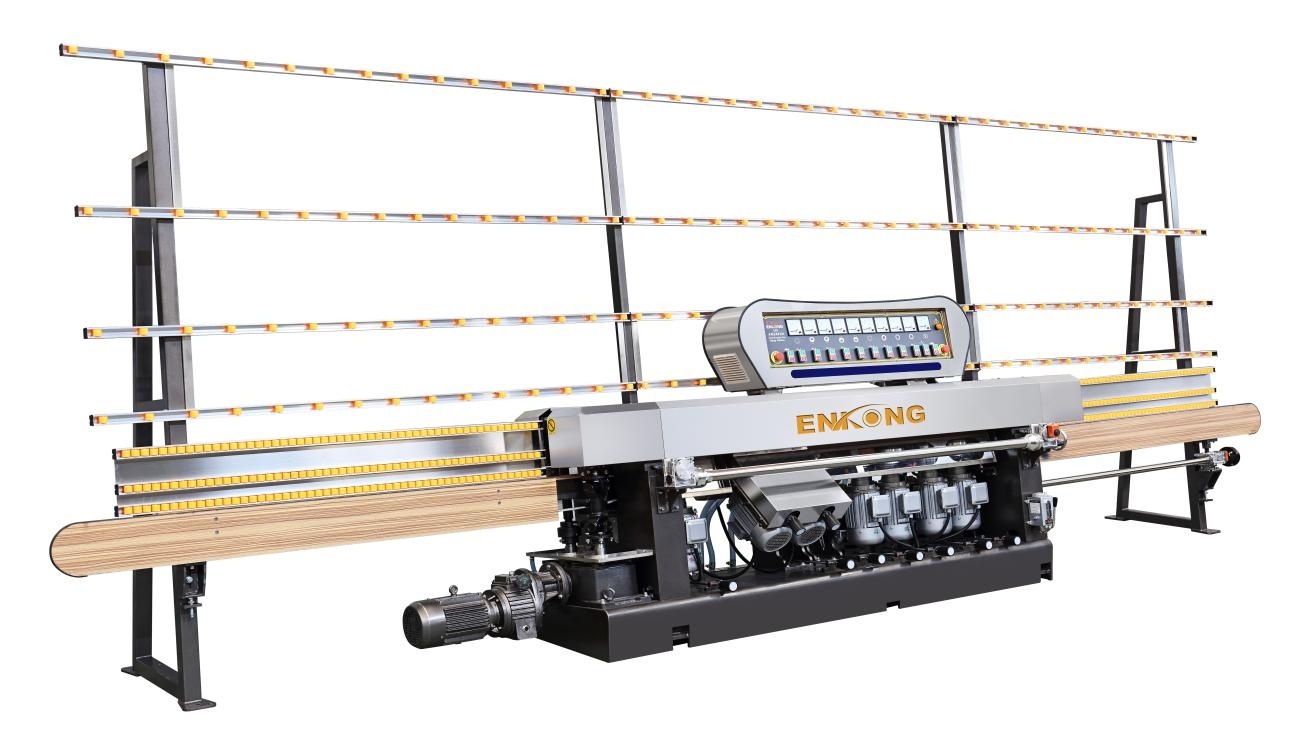

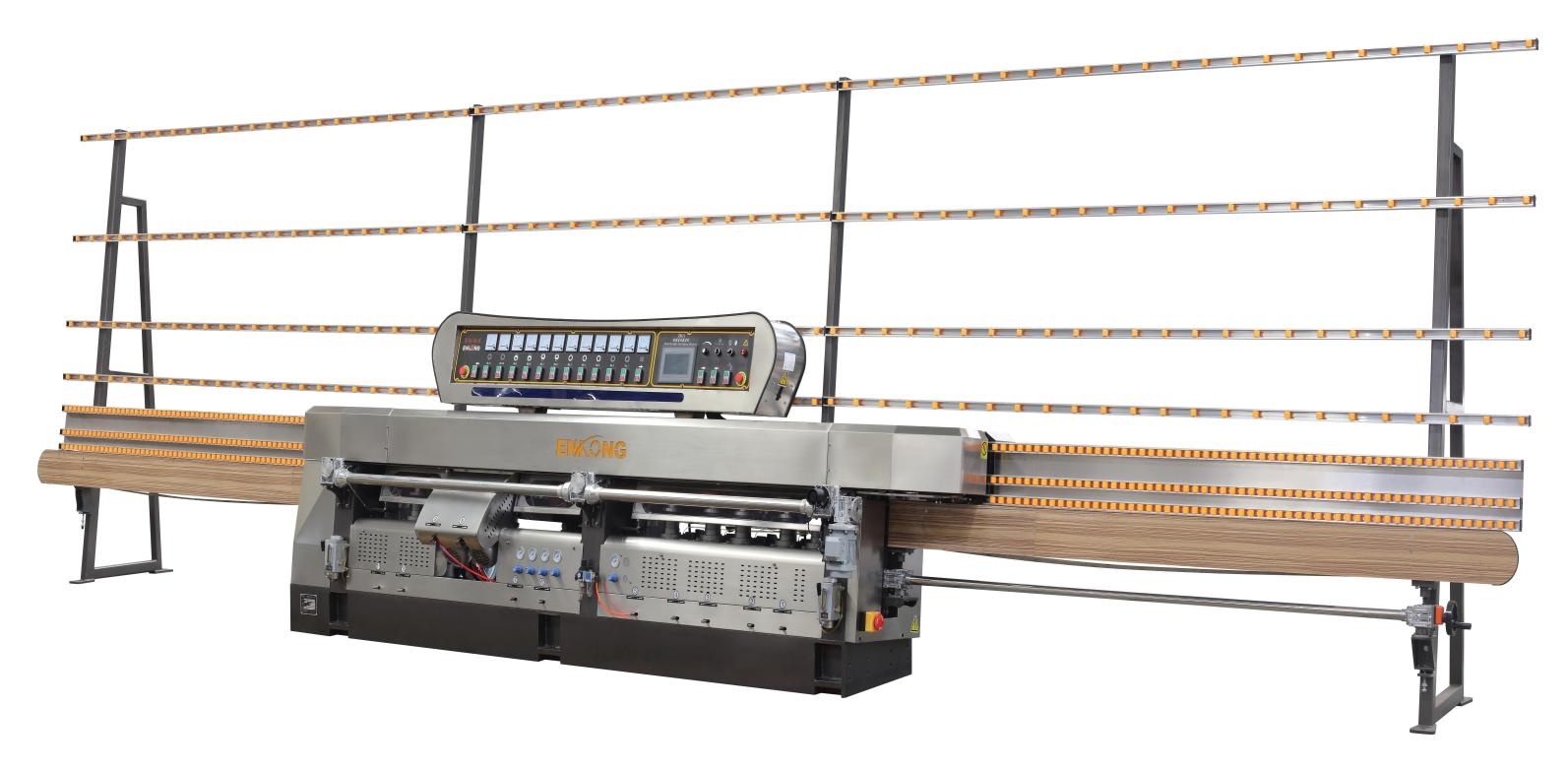

ZM9/ZM11 Glass Straight-line Edging Machine

Contents

1、Basic Description

2、 Scope of Application

3、Configuration Specification

4、Machine’s Details

5、 Main Parts Processing Technology

1.Basic Description

1. ZM9/ZM11 is suitable for processing straight-line edge & 45°arrises of glass sheet with various size and thickness,and rough grinding, fine grinding, polishing of flat edge and grinding of bottom edge can be completed in one time.

2.A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually.

3. Independent felt wheel and the cerium water recirculation system make the flat edge moreshining.

4. Input and output conveyor adopt timing belt which can improve the transmission precision.

5. The whole machine is well-structured and modularity design.It is easy to operate and has good performance.

6. Control elements are of well-know,such as Schneider, ABB..... which the motor with longerservice life and good stability.

7.The glass edger’s overall housing, fittings, baseis made of cast iron.

2.Scope of Application

ZM9/ZM11 is suitable for grinding architectural glass, decorative glass,furniture glass, home appliance glass.It is a necessary machine for glass deep processing factory.

3.Configuration Specification

1.The front beam movement is electrically adjusted.

2.Having rectangular steel pipe frame and strip guard.

3.The left and right columns, the base and the grinding head seat are welded parts, which have undergone thermal processing.

4.The water tank and shell shield are made of 201 stainless steel plate.

5.The glass input and output are driven by timing belt.

6.The input guide rail with synchronous lifting.

7.The main electric parts using Schneider.

8.Mode of operation: manual, digital display, plc

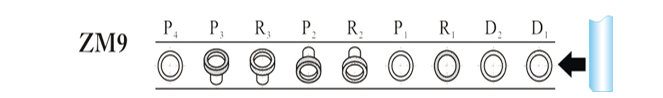

3-1.Wheel Distribution

NO. WHEEL NAME SPECIFICATION FUNCTION

NO.1 Diamond wheel Φ150×Φ12,100mesh Rough grinding

NO.2Diamond wheel Φ150×Φ12,180mesh

NO.3Resin wheel Φ150×Φ12,240mesh Chamfered edges

NO.4 Fine grinding wheel 10S40Φ150×Φ70×30

NO.5 Front arris resin wheel Φ130×Φ12×10×10,240mesh

NO.610S40 Front arris 10S40 wheelΦ130×Φ60×35

NO.7Rear arris resin wheel Φ130×Φ12×10×10,240mesh Fine grinding&Polish

NO.810S40 Rear arris 10S40 wheelΦ130×Φ60×35

NO.9 CE3/Wool wheel Φ150×Φ105×35

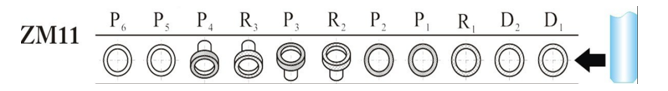

NO. WHEEL NAME SPECIFICATION FUNCTION

NO.1 Diamond wheel Φ150×Φ12,100mesh Rough grinding

NO.2 Diamond wheel Φ150×Φ12,180mesh

NO.3 Resin wheel Φ150×Φ12,240mesh

NO.4 Fine grinding wheel 10S40Φ150×Φ70×30

NO.5 Fine grinding wheel 10S40Φ150×Φ70×30

NO.6 Rear arris resin wheel Φ130×Φ12×10×10,240mesh Chamfered edges

NO.7 Rear arris 10S40 wheel Φ130×Φ60×35

NO.8Front arris resin wheel Φ130×Φ12×10×10,240mesh

NO.9 Front arris10S40 wheel Φ130×Φ60×35

NO.10Wool wheel Φ150×Φ105×35 Fine grinding&Polish

NO.11 Front arris10S40 wheel Φ150×Φ105×35

3-2.Technical Parameter

ZM9 Glass Straight-line Edging Machine

Processing glass thickness 3-25mm

Min.glass size 80*80mm

Processing speed 1.26-6.0m/min

Installation power 19.08kw

WeightAbout 3000kgs

Working hight 740mm

Voltage 220V/380V/415V;60HZ/50HZ(可定制)

ZM11 Glass Straight-line Edging Machine

Processing glass thickness 3-25mm

Min.glass size 80*80mm

Processing speed 1.26-6.0m/min

Installation power 22kw

Weightabout 4000kgs

Working hight 740mm

Voltage 220V/380V/415V;60HZ/50HZ(Customizable)

3-3.Electric box & operation method

Electrical control system

Mode of operation: manual, digital display,plc

The main electric parts using Schneider.

Optional operation method

1

Regular edition

Manual

It adopts a hand wheel to adjust the glass thickness,which is suitable for the straight-line edging machineonly.

2

Advanced Edition

Digital Display

There have digital meter onto the machine panel to adjust the glass thickness. You just need to increase or decrease the parameter you need by the relative switch, then machine can be adjust automatically.

3

Top Edition

PLC

Adopt Schneider Electric PLC and touch screen you can input the parameter you needand machine will adjust automatically.

4.Machine’s Details

Our advantage

The main machine

Suspension chain pads system

grinding motor

Speed control by stepless motor

Our advantage

Grinding wheels

Lubricating system

lifting structure

pillars during Heating treatment

5.Main parts processing technology

girder

CNC center

Adopt reinforcement design to prevent beam deformation

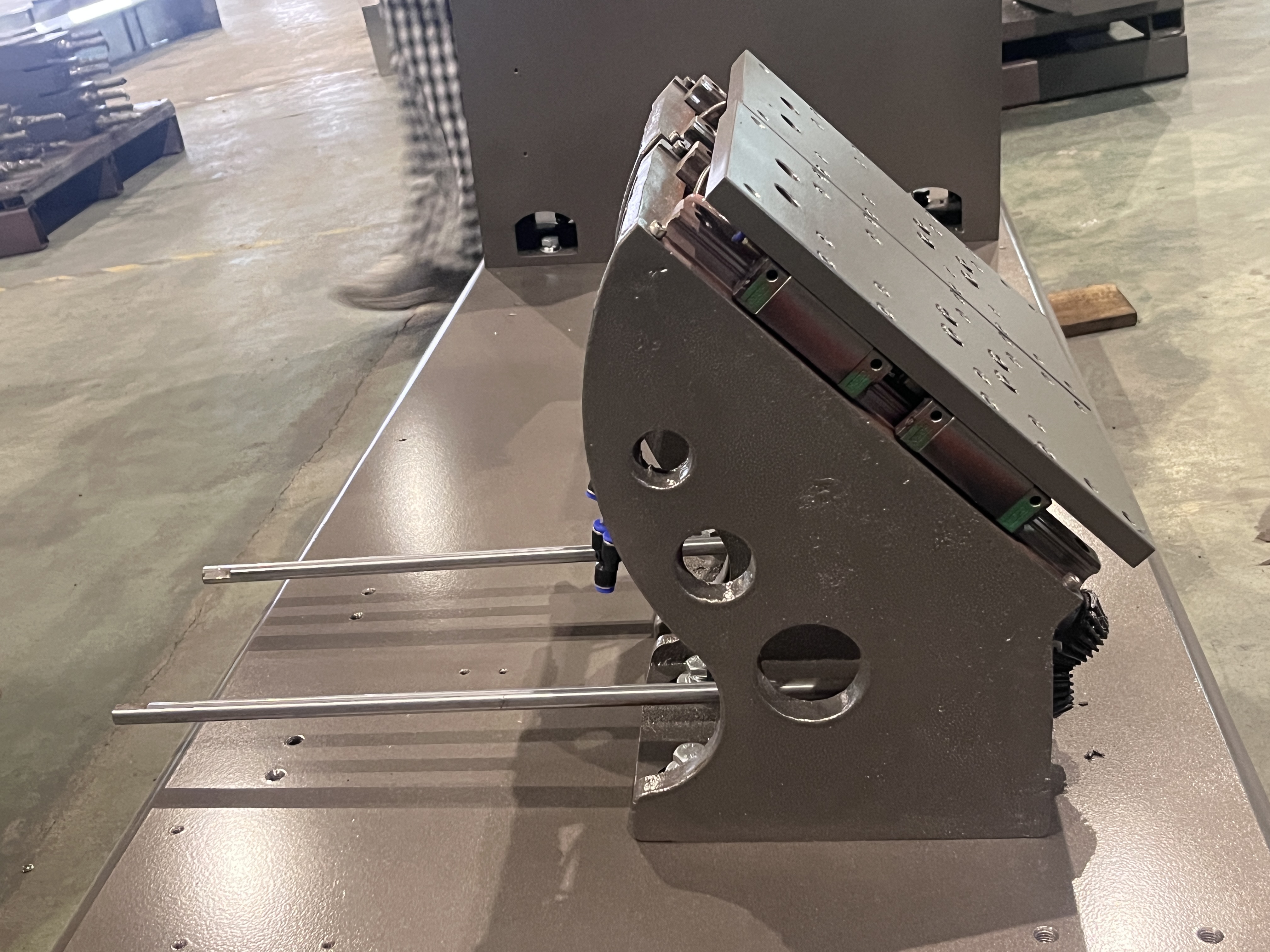

Dragging Plate Process

Linear guides are installed at the front and rear chamfered motor carriages

The front and rear corner dabbing motor dragging plate adopts linear sliding friction guide rail with adjust movement smoothly.

Appearance

The water tank and shell shield are made of 201 stainless steel plate.And it adopts stainless steel appearance,which looks like so simple and neat.

Grinding head water tank is stamped and formed, without welding, without cracks, and the surface is smooth.