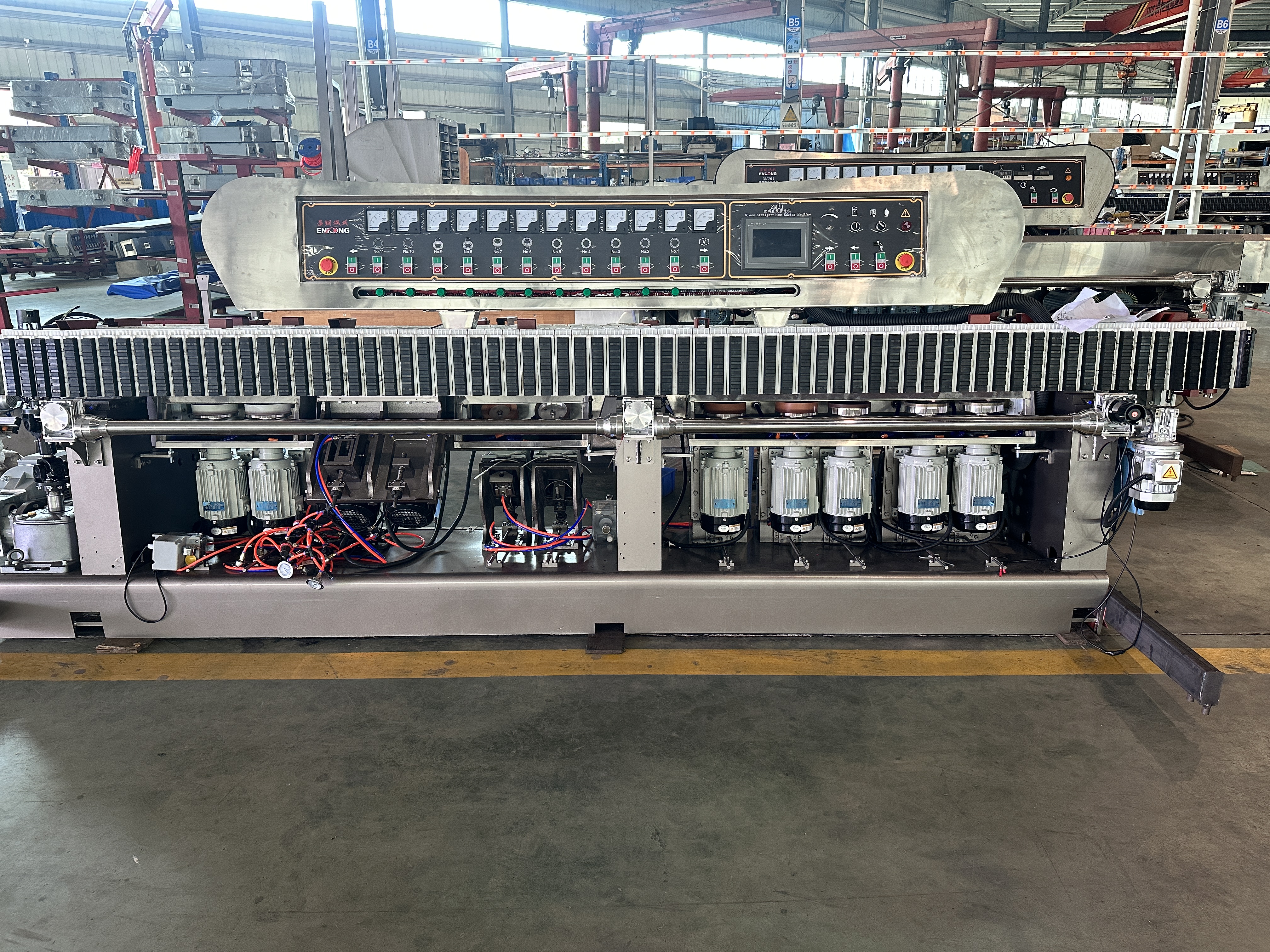

ENKONGS ZM11: Glass grinding machine, also known as glass grinder, is a specialized tool used in the glass industry to grind and polish the edges of glass panels. Enkongs glass edge sanding machine is essential for creating smooth and precise edges on glass, which is crucial for ensuring the quality and safety of glass products.The glass grinding machine consists of a motorized rotating grinding wheel that is used to grind down and shape the edges of glass panels. The glass edge sanding machine is equipped with adjustable settings that allow for precise control over the grinding process, ensuring that the edges are perfectly smooth and uniform.

The relentless pursuit of thinner, stronger, optically perfect glass across countless applications – from towering skyscrapers and designer furniture to high-definition displays and luxury mirrors – exposes the limitations of conventional equipment. Bottlenecks arise from slow polishing cycles, inconsistent edge quality (especially on delicate mirrored surfaces), high rejection rates, labor-intensive processes, and the inability to maintain perfection at scale. Traditional methods often leave subtle scratches, haze, or uneven edges that compromise aesthetics and functionality. Addressing these critical industry pain points, our engineering team focused on developing purpose-built solutions. The result is this synergistic trio: the transformative Glass Polishing Processing Machine for achieving optical clarity and scratch-free surfaces; the specialized Mirror Glass Edging Machine designed to handle delicate mirrored coatings with absolute precision; and the robust Glass Straight Line Edging Machine engineered for high-volume, flawless linear edge finishing. Each machine integrates advanced automation, sophisticated sensor feedback loops, intelligent process control, and rugged construction, guaranteeing consistent, breathtaking results shift after shift, project after project. The Glass Polishing Processing Machine addresses the final surface finish, the Mirror Glass Edging Machine protects the most sensitive coatings during shaping, and the Glass Straight Line Edging Machine ensures edge integrity meets structural and aesthetic demands.

The journey from a good glass surface to an exceptional one culminates with the Glass Polishing Processing Machine. This sophisticated system is engineered for fabricators demanding absolute clarity, a flawless scratch-free finish, and the elimination of even the subtlest surface haze or texture. Imagine transforming standard glass panels into crystal-clear sheets where light passes without distortion – this is the core mission of the Glass Polishing Processing Machine. Its power lies in a multi-stage, computer-controlled polishing process. Large, rotating polishing heads, equipped with progressively finer abrasives and specialized polishing compounds, move across the glass surface with controlled pressure and precise paths. The Glass Polishing Processing Machine utilizes advanced slurry management systems that continuously deliver the optimal polishing medium, while efficient extraction removes waste particles instantly, preventing them from causing secondary scratches. Real-time monitoring sensors track surface roughness, ensuring the machine automatically adjusts pressure, speed, and dwell time to achieve the target Ra (surface roughness average) value consistently across the entire panel, regardless of size.

Integrating the Glass Polishing Processing Machine into a production line often becomes a key differentiator, allowing fabricators to command premium prices for glass renowned for its exceptional clarity. Beyond aesthetics, a perfectly polished surface from the mirror glass edging machine is easier to clean and maintain, a critical factor in architectural and hospitality applications. The automation within themirror glass edging machine significantly reduces reliance on highly skilled manual polishers, ensuring consistent results independent of operator fatigue or variation. Witnessing the Glass Polishing Processing Machine transform a raw glass sheet into a pane of optical clarity is witnessing the removal of imperfections at a microscopic level – a testament to engineering precision dedicated to surface perfection. For manufacturers supplying the luxury market, aerospace, or high-tech displays, the Glass Polishing Processing Machine is not optional; it's the cornerstone of quality assurance.

The key to the Glass Straight Line Edging Machine's productivity is its ability to process multiple edges simultaneously or handle large sheets efficiently. Options for automatic loading and unloading further amplify throughput, creating a near-continuous flow of finished panels. Quick-change tooling systems allow for rapid transitions between different edge profiles or finishing sequences (e.g., rough grind to fine polish). Efficient, high-volume coolant systems are integral, keeping the grinding zone cool, flushing away glass particles, and ensuring a smooth, chip-free finish while extending tool life. For factories supplying the construction industry, kitchen manufacturers, or large-scale interior fit-outs, the Glass Straight Line Edging Machine is fundamental to profitability and competitiveness. Its exceptional throughput dramatically reduces per-unit processing costs. Its unwavering consistency minimizes customer returns and rework, protecting profit margins and reputation. Integrating a high-performance mirror glass edging machine streamlines production lines, enabling manufacturers to meet aggressive deadlines and fulfill large contracts with confidence, knowing every straight edge meets the required specification. The relentless efficiency and reliability of the Glass Straight Line Edging Machine make it the backbone of any high-volume glass fabrication facility focused on quality and speed for linear components.

This integrated approach eliminates bottlenecks and maximizes resource utilization. Workloads are dynamically allocated based on real-time machine availability and job requirements. Data streams from all three machines – the Glass Polishing Processing Machine, the Mirror Glass Edging Machine, and the Glass Straight Line Edging Machine – feed into a Manufacturing Execution System (MES), providing unparalleled visibility into production status, Overall Equipment Effectiveness (OEE), maintenance schedules, and quality metrics across the entire shop floor. Quality control is inherently enhanced. Each machine's built-in monitoring – the surface scanning of the mirror glass edging machine, the coating protection sensors of the mirror glass edging machine, and the edge tracking of the Glass Straight Line Edging Machine – creates a comprehensive quality assurance network. Predictive maintenance, powered by analytics from the trio, prevents costly unplanned downtime. Material flow and inventory management become significantly more efficient. Crucially, this integration provides unmatched flexibility. A sudden large order for standard beveled edges? Ramp up the Glass Straight Line Edging Machine. A complex project requiring optically perfect oversized panels? The Glass Polishing Processing Machine handles it. A prestigious contract for large, flawless architectural mirrors? The mirror glass edging machine ensures success. Investing in this synergistic suite – the perfection-driven Glass Polishing Processing Machine, the protective precision of the Mirror Glass Edging Machine, and the high-volume prowess of the Glass Straight Line Edging Machine – future-proofs operations, delivering the surface quality, specialized handling, linear efficiency, and data-driven intelligence needed to lead global markets.