The edging production line is beginning on 1# edging machine, and the transfer table is automatically turned to the long side of the 2# grinding machine. The processing speed is 1-15m/min.

Technical Data:

Number of Spindles: 24

Max. glass dimension: Up to 4200(option: Jumbo Glass Size can be customize)

Min. glass size: 300x300 (option: 250x250)

Glass thickness: 3~25 mm

Working Speed: 1-15m/min

Width adjustment Speed: 4m/min (optional:8m/min)

Max. edge grinding: 3mm

Tolerance of the diagonal(1000x1000): ±0.5mm

Tolerance on the parallelism(mm): ±0.2mm

Arris width:1-5mm

Total power: about 65KW

Electrical Parts

Item | Manufacture | Origin |

Low-Voltage apparatus | Schneider | France |

button | Takahashi | CHINA |

Inverter | Delta | Taiwan, China |

transformer | Erbian | China |

Encoder | Koyo | Japan |

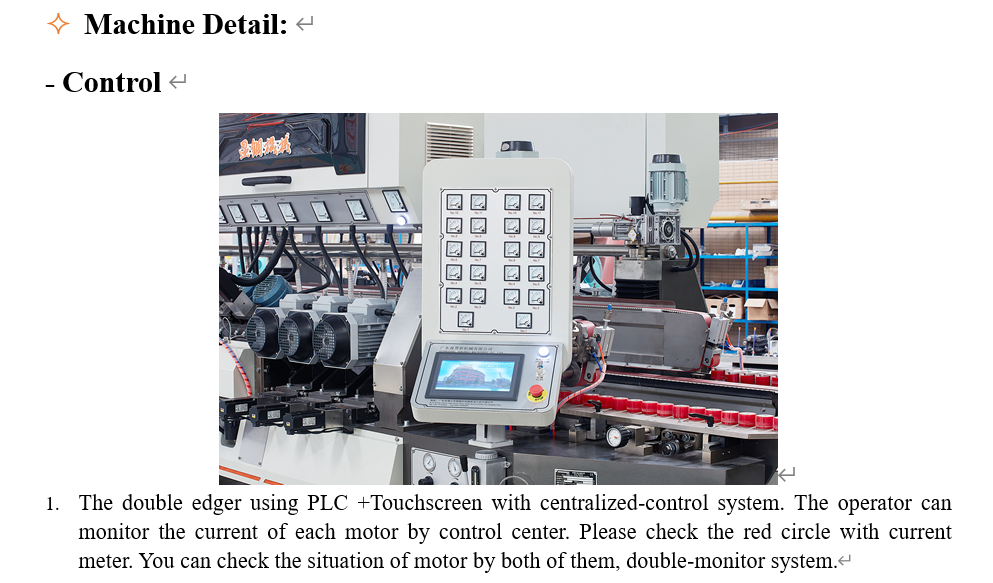

PLC | Delta / Wing Hong | Taiwan, China |

touch screen | Kunluntongtai | China |

Servo system | Delta / Wing Hong | Taiwan, China |

1. Motor configuration:

- Conveyor motor: variable frequency motor 2.2KW

- Roller conveyor motor 1: variable frequency motor 1.5KW

- Roller conveyor motor 2: variable frequency motor 1.5KW

2. Technical parameters:

1 | Minimum size of the transfer glass: | 350mm * 350mm |

2 | Maximum size of the transfer glass | 2500mm * 1500mm |

3 | Thickness of the transfer glass | 3-25mm |

4 | Total power | 5.2KW |

5 | Dimensions | 8100mm * 2900mm * 1000mm |

Remark: When the size of the transfer glass changes, the external dimensions change accordingly. | ||

Glass processing is a complex and intricate field that requires precision and efficiency. To achieve the desired finish and quality, several specialized machines are employed.

The glass double sides edger is a versatile machine designed to process both sides of the glass simultaneously. This machine is particularly useful for producing glass products with uniform edges, such as glass doors, windows, and table tops. The double sides edger ensures that both edges of the glass are precisely and evenly cut, providing a clean and polished appearance.

The glass double sides edger typically consists of two main components: the cutting head and the conveyor system. The cutting head is responsible for the actual edging process, while the conveyor system transports the glass through the machine. Advanced models of double sides edgers are equipped with multiple cutting heads, allowing for simultaneous processing of both edges, which significantly increases production efficiency.

The straight edge grinding machine is designed to grind the edges of glass sheets to create a smooth, straight edge. This machine is essential for glass products that require a clean, finished edge, such as glass shelves and glass panels. The straight edge grinding machine utilizes a series of abrasive wheels to grind the edge of the glass, removing any roughness or imperfections.

The straight edge grinding machine typically features a conveyor system that transports the glass sheet through the machine, and a set of grinding wheels that rotate at high speeds to grind the edge. The machine can be adjusted to accommodate different glass thicknesses and edge profiles, ensuring flexibility in the production process.

The glass edge finishing machine is used to provide a final finish to the edges of glass sheets after they have been cut and ground. This machine is crucial for achieving a highquality, aesthetically pleasing appearance on the glass edge. The glass edge finishing machine can create various finishes, such as polished, beveled, or flat edges, depending on the specific requirements of the glass product.

The glass edge finishing machine typically consists of a series of polishing wheels or pads that are applied to the edge of the glass. These wheels or pads are made from different materials, such as diamond, to achieve the desired finish. The machine can be adjusted to accommodate different glass thicknesses and edge profiles, ensuring versatility in the production process.

The glass corner polishing machine is designed to polish the corners of glass sheets, ensuring a smooth and safe finish. This machine is particularly important for glass products that are handled frequently or have exposed corners, such as glass furniture and glass doors. The glass corner polishing machine utilizes a combination of abrasive and polishing wheels to achieve the desired corner finish.

The glass corner polishing machine typically features a conveyor system that transports the glass sheet through the machine, and a set of polishing wheels that are specifically designed to polish the corners. The machine can be adjusted to accommodate different glass thicknesses and corner profiles, ensuring flexibility in the production process.

The glass double sides edger, straight edge grinding machine, glass edge finishing machine, and glass corner polishing machine are all essential tools in the glass processing industry. Each machine plays a unique role in achieving the desired finish and quality of glass products. By understanding the functions and features of these machines, glass processors can ensure that their products meet the highest standards of quality and appearance. The combination of precision, efficiency, and versatility offered by these machines enables glass manufacturers to produce a wide range of glass products, satisfying the diverse needs of the market.