INTRODUCTION

Glass is a versatile material used in a wide range of industries, from construction to automotive. However, the process of cutting and edging glass can be time-consuming and labor-intensive. Glass edging machines are a revolutionary solution that improves efficiency in glass processing, making it faster and more precise. In this article, we will explore how glass edging machines can benefit businesses in the glass industry.

One of the key benefits of using glass edging machines is increased productivity. These machines are designed to cut, grind, and polish glass quickly and accurately, reducing the time and manpower required for these tasks. With a glass polishing machine, businesses can process glass in a fraction of the time it would take using traditional methods, allowing them to produce more glass products in a shorter period;

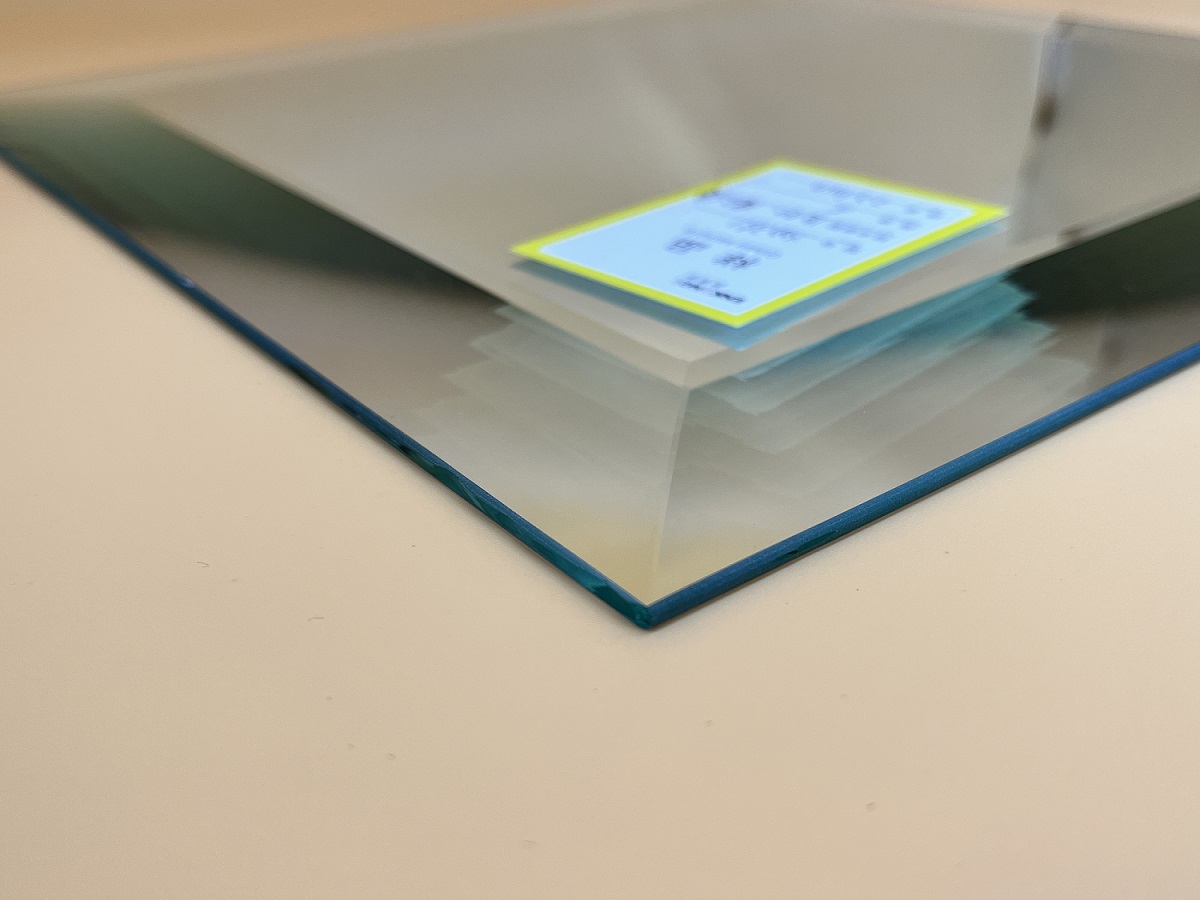

Glass edging machines are equipped with advanced technology that ensures precise cutting and edging of glass. This results in glass products that are uniform in size and shape, with smooth edges that are free from imperfections. The high level of precision offered by glass polishing machines not only enhances the quality of the glass products but also reduces the need for rework, saving businesses time and money.

Glass edging machines are versatile tools that can be used for a wide range of glass processing tasks, from cutting and shaping to polishing and beveling. This versatility allows businesses to perform multiple operations on glass using a single machine, eliminating the need for separate equipment for each task. By investing in a glass edging machine, businesses can streamline their glass processing operations and increase their overall efficiency.

While glass polishing machines may require an initial investment, they can ultimately lead to cost savings for businesses in the long run. By reducing the time and labor required for glass processing, these machines help businesses lower their production costs and increase their profit margins. Additionally, the high level of precision offered by glass polishing machines minimizes waste and rework, further reducing costs for businesses.

Glass processing can be a hazardous task, with the risk of injury from sharp edges and flying glass shards. Glass edging machines are equipped with safety features such as protective shields and automatic shut-off mechanisms, which help prevent accidents and protect workers from harm. By using glass edging machines, businesses can create a safer working environment for their employees and reduce the risk of workplace injuries.

Conclusion

Glass edging machines are a valuable tool for businesses in the glass industry, offering a range of benefits that improve efficiency in glass processing. From increased productivity and improved precision to cost savings and enhanced safety, these glass polishing machines are a smart investment for businesses looking to streamline their glass processing operations. By incorporating glass edging machines into their workflow, businesses can boost their productivity, enhance the quality of their glass products, and ultimately achieve greater success in the competitive glass industry.