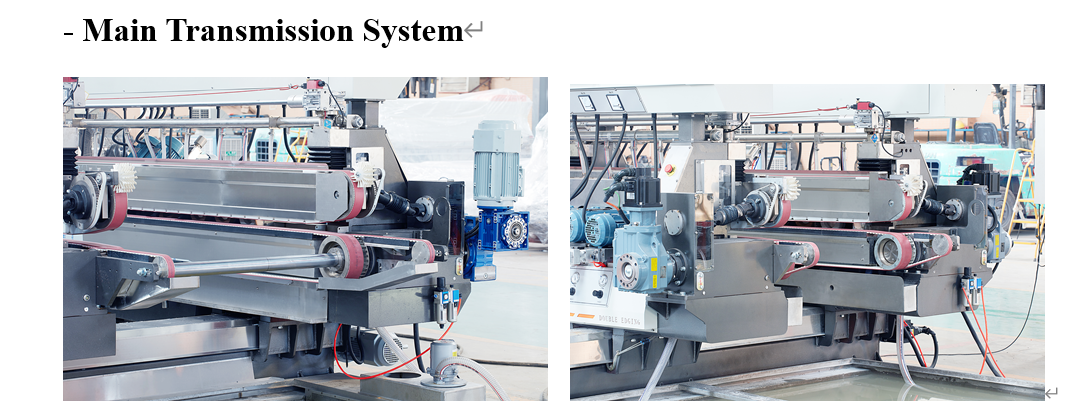

The main gear box shaft sleeve adopts through sleeve structure, using high precision roller bearings, stable and reliable operation, long service life, reduce maintenance cost. Servo motor transmission is also available for option.

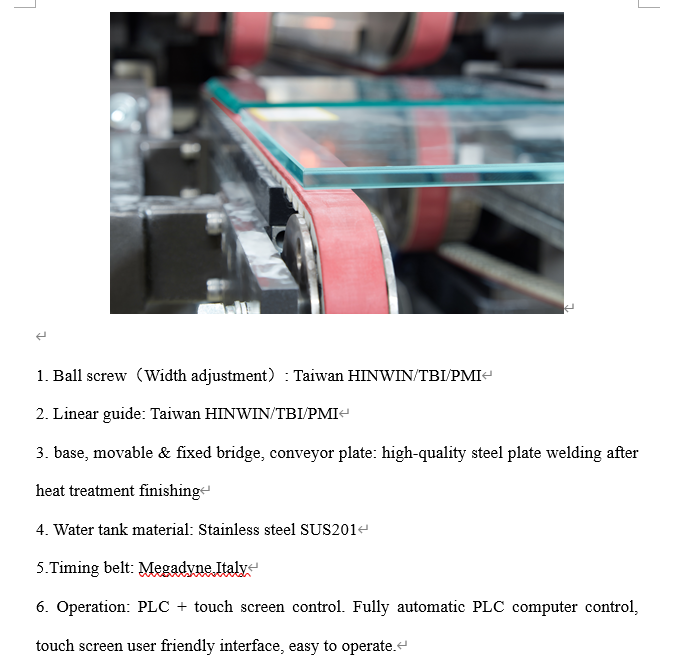

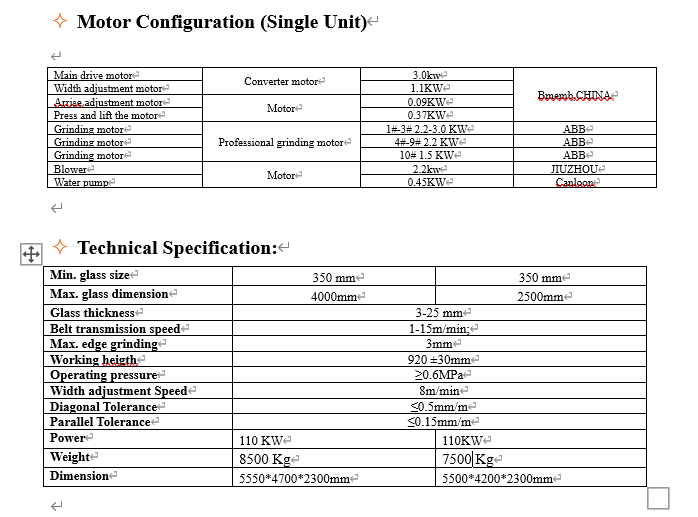

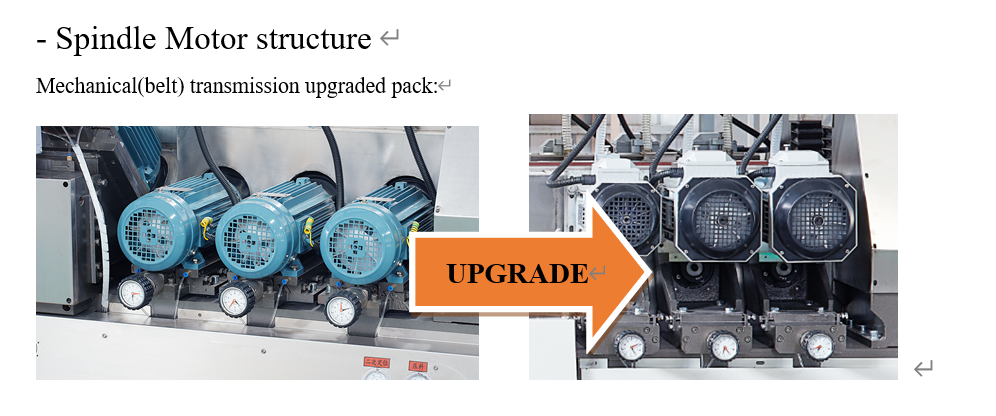

1. Standard Model: High performance ABB motors first one adopts 3kw. Inside of the sliding part adopt the bronze nut work with adjustment screw rod to reduce the gap, more flexible and durable.

2. Mechanical (belt) transmission: with 4200rpm mechanical transmission by belt driven. Spindles shaft rotation at 4200rpm/min. The shaft can tolerant up to 12000rpm/min maximum, however, only using 1/3 of total speed capacity. The processing speed is upon 15m/min with polishing. Grinding ability has improved

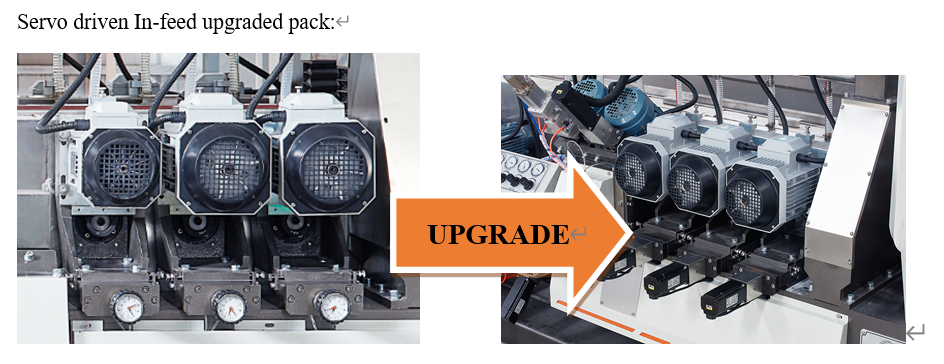

3. Mechanical (belt) transmission with Servo driven In-feed arrangement: Fully automatic wheel adjustment. Precise calculation between wheel and material. Avoiding uneven grinding caused by human error. Stepping into the next automation level.

1. Motor configuration:

- Conveyor motor: variable frequency motor 2.2KW

- Roller conveyor motor 1: variable frequency motor 1.5KW

- Roller conveyor motor 2: variable frequency motor 1.5KW

2. Technical parameters:

1 | Minimum size of the transfer glass: | 350mm * 350mm |

2 | Maximum size of the transfer glass | 2500mm * 1500mm |

3 | Thickness of the transfer glass | 3-25mm |

4 | Total power | 5.2KW |

5 | Dimensions | 8100mm * 2900mm * 1000mm |

Remark: When the size of the transfer glass changes, the external dimensions change accordingly. | ||